Basic Info.

Model NO.

Kwikstage scaffolding

Supporting Mode

Projecting Scaffolding

Lapping Form

Double Scaffolding

Erection Position

External Scaffolding

Scaffolding Part Type

Scaffolding Couplers

Construction Properties

Building Scaffold

Surface Treatmer

Hot Dipped Galvanized/Painting

Certification

AS/NZS 1576/1577

Transport Package

Steel Pallet

Specification

3.6m/3.2m/2.7m/2.1m/1.7m

Trademark

ADTO

Origin

Tianjin, China

Production Capacity

1000 Ton/Tons Per Month

Product Description

Kwikstage scaffolding can be fastened once connected, so it is also called quickstage scaffolding system due to its speedy installation. Kwikstage Scaffolding is the one of the best scaffolding systems, reliable in Australia for its flexibility, strength and easy of installation.

This scaffolding system saves erection and dismantling time, reducing labour costs and creating time for what matters most -getting the job done!

Main Componets:

Kwikstage standard

Material: Q235, 48.3*4mm

Length: 0.5m, 1.0m, 1.5m, 2.0m, 2.5m, 3.0m

Surface finish: Painted/Galvanized

Standard: AS/NZS 1576

Kwikstage Ledger

Material: Q235, 48.3*3.2mm

Length: 0.5m, 0.7m, 0.8m, 1.0m, 1.2m, 1.8m, 2.4m, 3.0m

Surface finish: Painted/Galvanized

Standard: AS/NZS 1576

Kwikstage Transom

Material: Q235, 50*50*5mm

Length: 0.5m, 0.7m, 0.8m, 1.0m, 1.2m, 1.8m, 2.4m.

Surface finish: Painted/Galvanized

Standard: AS/NZS 1576

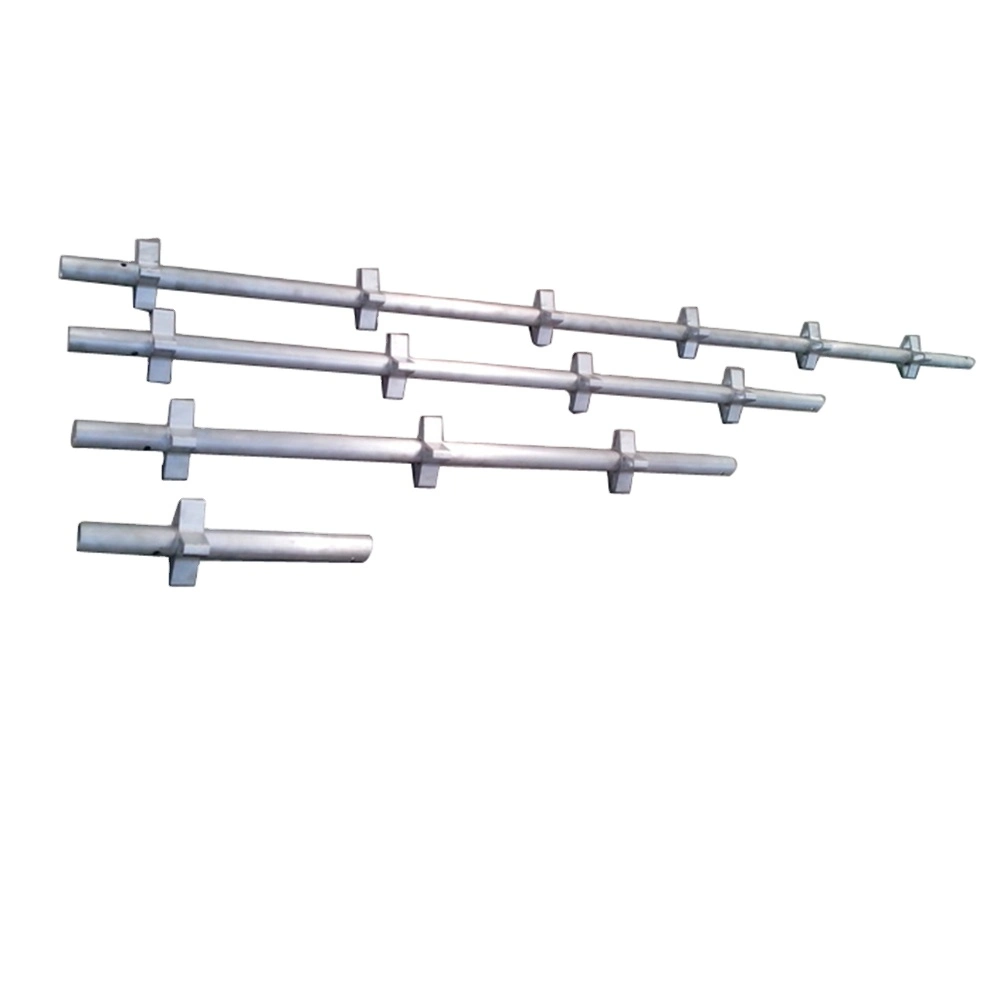

Kwikstage Diagonal Brace

Material: Q235, 48.3*3.2mm

Length: 1.7m, 2.1m, 2.7m, 3.2m, 3.6m

Surface finish: Painted/Galvanized

Standard: AS/NZS 1576

Kwikstage Tie Bar

Material: Q235, 40*40*4mm

Length: 0.5m, 0.7m, 1.0m, 1.2m, 1.8m, 2.4m

Surface finish: Painted/Galvanized

Standard: AS/NZS 1576

Kwikstage Steel Board

Material: 230*63mm

Length: 0.54m, 0.74m, 1.03m, 1.25m, 1.81m, 2.42m, 3.07m

Surface finish: Painted/Galvanized

Standard: AS/NZS 1577

Packaging & Delivery:

Packaging Details

wooden pallet, steel pallet, or as the requirment of clients

Port:Tianjin port

Lead Time:

wooden pallet, steel pallet, or as the requirment of clients

Port:Tianjin port

Lead Time:

| Quantity(metric tons) | 1 - 500 | >500 |

| Est. Time(days) | 30 | To be negotiated |

Company Profile:

About Us

ADTO group was established in 1998. It's a building materials supplier integrating R&D, production, sales and logistics. Its products include all kinds of scaffoldings, all types of formworks. For these products, ADTO owns 4 advanced manufacturing bases, equipped with top line machines in Tianjin, Hubei and other two Provinces.

Quality and safety builds future is ADTO Group's belief. Since the foundation of our group company, we have rapidly grown to be the scaffolding & aluminum formwork leading brand in China with more than 50 national patents.

Showroom:

Production Line:

Exhibition Experience:

Certification:

Our Advantages:

a) Durability: Kwikstage scaffold is made of tough material and provides long-term benefits.

b) Adaptability: It is adaptable to different construction sites and all types of buildings.

c) Increased productivity: it can sustain many workers at the same time, thereby increasing productivity.

d) Lower maintenance costs: It does not require costly maintenance.

e) No loose fittings: the wedgelock system without any screws or nuts

f) Labor saving: it can be erected and dismantled easily and fast.