Basic Info.

Supporting Mode

Floor Type Scaffolding

Lapping Form

Full Scaffolding

Erection Position

External Scaffolding

Move Method

Attached Lifting Scaffolding

Scaffolding Part Type

Scaffolding Frames

Construction Properties

Building Scaffold

Sruface Treatment

Galvanized / Painted / Powder Coated

Steel Grade

Q345 / Q235

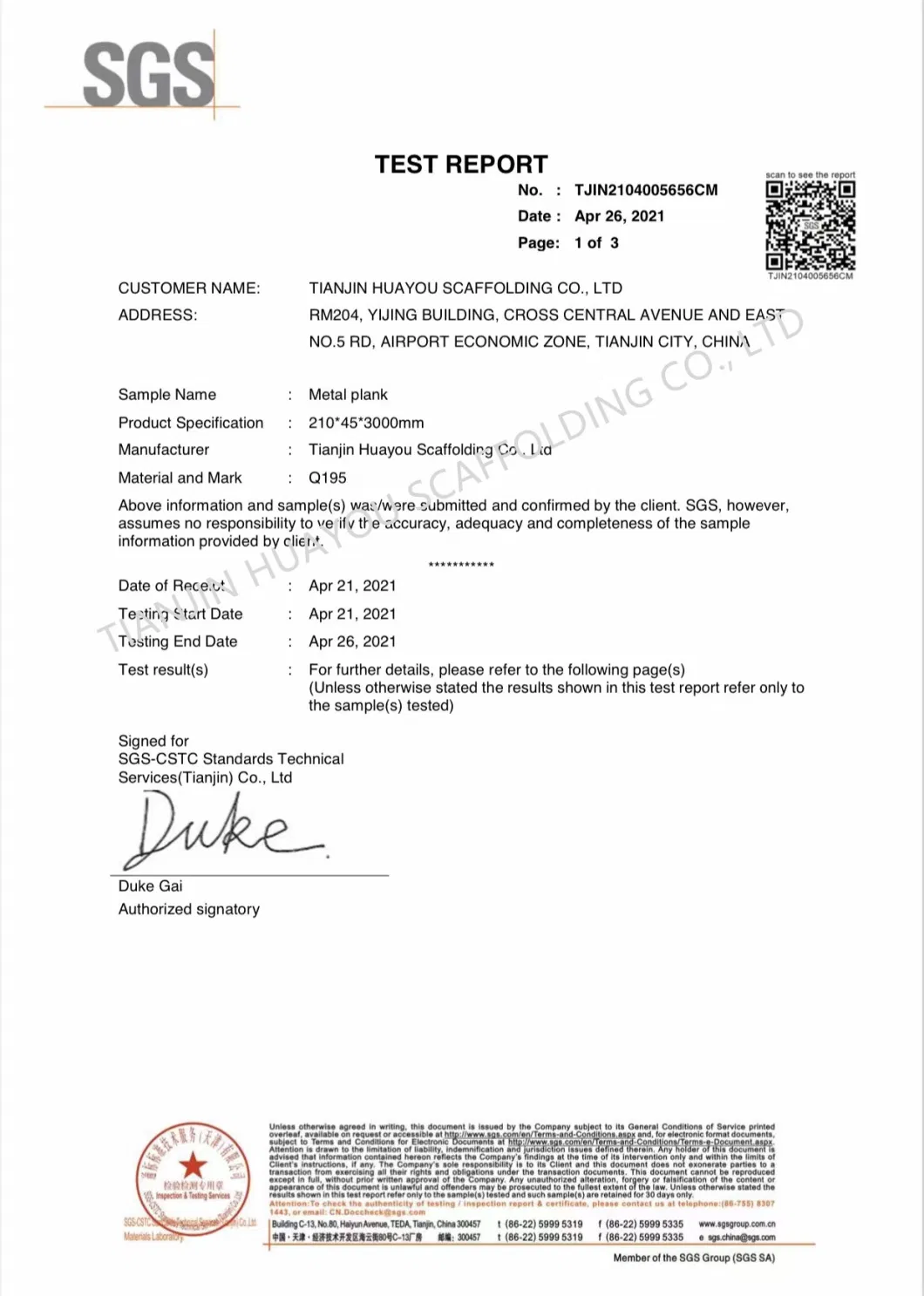

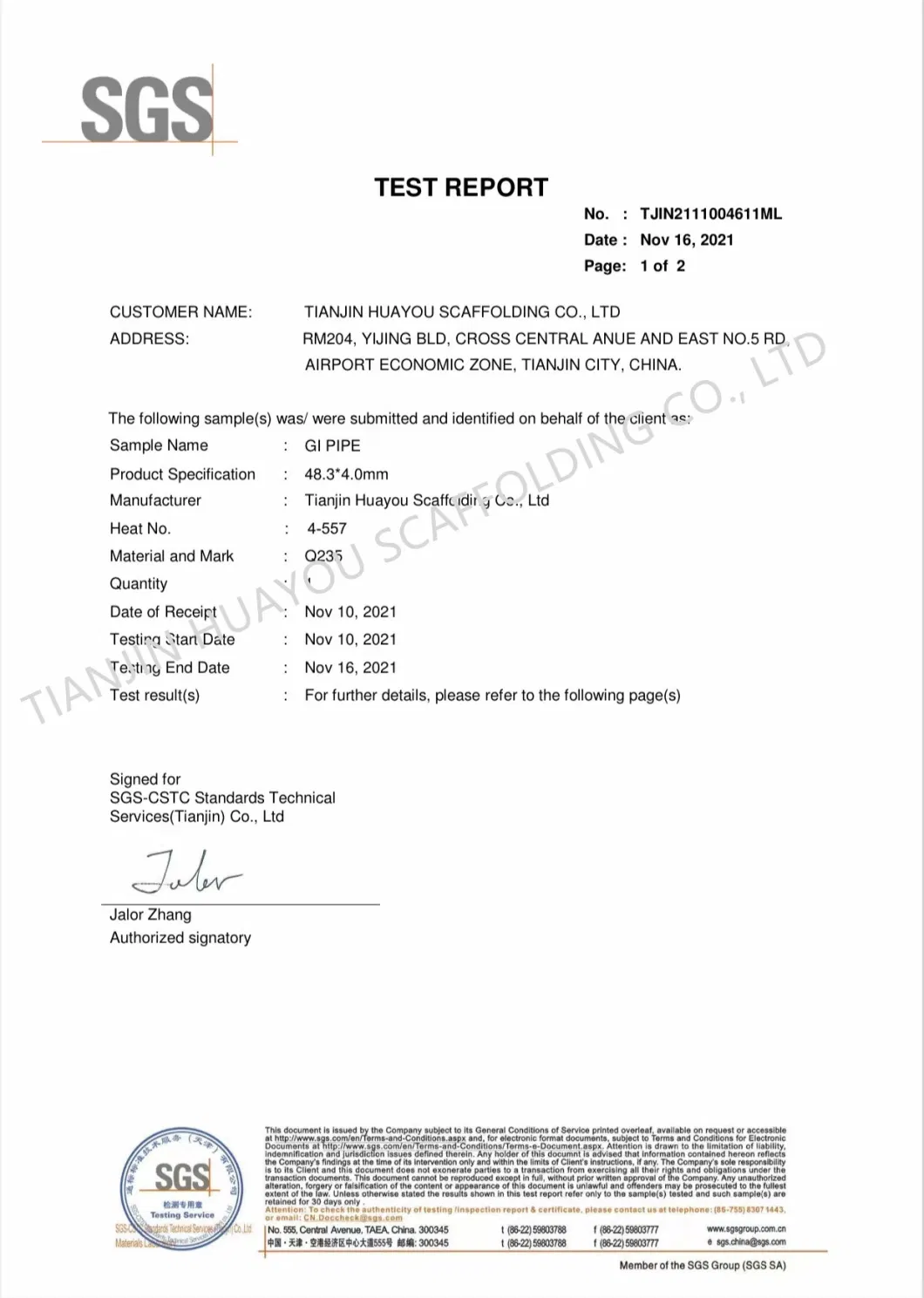

Certificate

SGS/ISO

MOQ

1PC

OEM

Available

Connect Method

V Lock

Application

Building/Tunnel/Bridge Construction

Advantage

Heavy Loads, Stable, Flexible, Easy Assembling

Transport Package

by Bundle or by Pallet, Suitable for Sea Transport

Specification

48.3mm

Trademark

HUAYOU

Origin

China

HS Code

7308400000

Production Capacity

50000tons /Year

Product Description

Kwikstage scaffolding is one of the important scaffolding systems in the world. As a modular scaffolding system, it can be used in different projects as external or internal support. Its advantages like Heavy Loads, Stable, Flexible, Easy Assembling make it widely used at home and abroad.

1) Kwikstage Scaffolding Vertical/Standard

2) Kwikstage Scaffolding Ledger/Horizontal

3) Kwikstage Scaffolding Transoms

4) Kwikstage Scaffolding Return Transom

5) Kwikstage Scaffolding Platform Bracket

6) Kwikstage scaffolding Bracing/Diagonal

7) Kwikstage Scaffolding Tie Bars

8) Kwikstage Steel Board

PRODUCT DETAILS:

PACKAGE & LOADING:

-By bundle or by steel pallet, as requested, suitable for sea transportation.

CERTIFICATE:

COMPANY PROFILE:

Warmly welcome your inquiry support.

OTHER RELATED PRODUCTS:

FAQ:

Q1: Where is the loading port?

A: Tianjin Xin port

Q2: What's the MOQ of the product?

A: Different item has different MOQ, can be negotiated.

Q3: What certificates do you have?

A: We have ISO 9001, SGS etc.

Q4: Can I get some samples?

A: Yes, Sample is free, but shipping cost is on your side.

Q5: How long is the production cycle after ordering?

A: Generally need around 20-30 days.

Q6: What is the payment methods?

A: T/T or 100% irrevocable LC at sight, can be negotiated.

1) Kwikstage Scaffolding Vertical/Standard

Available in Painted steel tubes with V pressings in clusters at 495mm intervals.

| NAME | LENGTH (M) | NORMAL SIZE (MM) | SURFACE TREATMENT | STEEL GRADE |

| Vertical/Standard | L=0.5 | OD48.3, Thk 3.0-4.0 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235/Q355 |

| Vertical/Standard | L=1.0 | OD48.3, Thk 3.0-4.0 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235/Q355 |

| Vertical/Standard | L=1.5 | OD48.3, Thk 3.0-4.0 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235/Q355 |

| Vertical/Standard | L=2.0 | OD48.3, Thk 3.0-4.0 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235/Q355 |

| Vertical/Standard | L=2.5 | OD48.3, Thk 3.0-4.0 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235/Q355 |

| Vertical/Standard | L=3.0 | OD48.3, Thk 3.0-4.0 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235/Q355 |

2) Kwikstage Scaffolding Ledger/Horizontal

Available in Painted steel tubes 48.3X 3.2mm

Fit into upper V pressings on standards.

| NAME | LENGTH (M) | SURFACE TREATMENT | STEEL GRADE | CUSTERMIZED |

| Ledger/Horizontal | L=0.5 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235/Q355 | YES |

| Ledger/Horizontal | L=0.8 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235/Q355 | YES |

| Ledger/Horizontal | L=1.0 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235/Q355 | YES |

| Ledger/Horizontal | L=1.2 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235/Q355 | YES |

| Ledger/Horizontal | L=1.8 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235/Q355 | YES |

| Ledger/Horizontal | L=2.4 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235/Q355 | YES |

| Ledger/Horizontal | L=3.0 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235/Q355 | YES |

3) Kwikstage Scaffolding Transoms

Fit into lower V pressings on Standards

Flanges provide seating for decking components .

| NAME | LENGTH (M) | SURFACE TREATMENT | STEEL GRADE | CUSTORMIZED |

| Transom | L=0.5 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235 | YES |

| Transom | L=0.8 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235 | YES |

| Transom | L=1.0 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235 | YES |

| Transom | L=1.2 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235 | YES |

| Transom | L=1.8 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235 | YES |

| Transom | L=2.4 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235 | YES |

| Transom | L=3.0 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235 | YES |

4) Kwikstage Scaffolding Return Transom

| NAME | LENGTH (M) | SURFACE TREATMENT | STEEL GRADE | CUSTOMIZED |

| Return Transom | L=0.8 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235 | YES |

| Return Transom | L=1.2 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235 | YES |

| NAME | WIDTH (MM) | SURFACE TREATMENT | STEEL GRADE | CUSTOMIZED |

| Platform Bracket | 230 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235 | YES |

| Platform Bracket | 460 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235 | YES |

| Platform Bracket | 690 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235 | YES |

Available in Painted steel tubes 48.3X 3.2mm

Fit into outside V pressings on standard.

| NAME | LENGTH (M) | SURFACE TREATMENT | STEEL GRADE | CUSTOMIZED |

| Bracing/Diagonal | L=1.83 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235/Q355 | YES |

| Bracing/Diagonal | L=2.75 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235/Q355 | YES |

| Bracing/Diagonal | L=3.53 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235/Q355 | YES |

| Bracing/Diagonal | L=3.66 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235/Q355 | YES |

7) Kwikstage Scaffolding Tie Bars

Steel angle with curved lugs at each end.Fit into 2 and 3 board platform brackets

Used to prevent spreading of 2 and 3 board platform brackets.

| NAME | LENGTH(M) | MATERIAL SIZE(MM) | SURFACE TREATMENT | STEEL GRADE | CUSTOMIZED |

| Tie Bar | L=0.5 | 40*40*4 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235 | YES |

| Tie Bar | L=0.7 | 40*40*4 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235 | YES |

| Tie Bar | L=1.0 | 40*40*4 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235 | YES |

| Tie Bar | L=1.2 | 40*40*4 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235 | YES |

| Tie Bar | L=1.8 | 40*40*4 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235 | YES |

| Tie Bar | L=2.4 | 40*40*4 | Hot Dip Galv./ Electro-Galv./Power coated/Painted | Q235 | YES |

8) Kwikstage Steel Board

| Name | LENGTH(M) | SIZE (MM) | SURFACE TREATMENT | STEEL GRADE |

| Steel Board | L=0.54 | 230*63*1.5 | Pre-Galv./Hot Dip Galv. | Q195/Q235 |

| Steel Board | L=0.74 | 230*63*1.5 | Pre-Galv./Hot Dip Galv. | Q195/Q235 |

| Steel Board | L=1.03 | 230*63*1.5 | Pre-Galv./Hot Dip Galv. | Q195/Q235 |

| Steel Board | L=1.25 | 230*63*1.5 | Pre-Galv./Hot Dip Galv. | Q195/Q235 |

| Steel Board | L=1.81 | 230*63*1.5 | Pre-Galv./Hot Dip Galv. | Q195/Q235 |

| Steel Board | L=2.42 | 230*63*1.5 | Pre-Galv./Hot Dip Galv. | Q195/Q235 |

| Steel Board | L=3.07 | 230*63*1.5 | Pre-Galv./Hot Dip Galv. | Q195/Q235 |

PRODUCT DETAILS:

PACKAGE & LOADING:

-By bundle or by steel pallet, as requested, suitable for sea transportation.

CERTIFICATE:

COMPANY PROFILE:

Tianjin Huayou Scaffolding Co., Ltd is located in Tianjin City, which is the largest manufacturing base of steel and scaffolding products. Furthermore, it is the north biggest port city that easier to transport cargo to all over the world.

We specialize in the production and sales of various scaffolding products, such as Ringlock system, steel Board, Frame system, Jack base, Pipes and fittings, Couplers, Cuplock system, Kwickstage system, Aluminuim system and other scaffolding or formwork accessories. With the effort of over 10 years experience team, Huayou products has been exported to different countries and clients cover different areas like South East Asia market, Middle East Market, Europe, America, Austrilia etc.

Our principle: "Quality First, Customer Foremost and Service Ultmost." We devote ourselves to meet your requirements and promote our mutually beneficial cooperation.

Warmly welcome your inquiry support.

OTHER RELATED PRODUCTS:

FAQ:

Q1: Where is the loading port?

A: Tianjin Xin port

Q2: What's the MOQ of the product?

A: Different item has different MOQ, can be negotiated.

Q3: What certificates do you have?

A: We have ISO 9001, SGS etc.

Q4: Can I get some samples?

A: Yes, Sample is free, but shipping cost is on your side.

Q5: How long is the production cycle after ordering?

A: Generally need around 20-30 days.

Q6: What is the payment methods?

A: T/T or 100% irrevocable LC at sight, can be negotiated.