Basic Info.

Supporting Mode

Floor Type Scaffolding

Lapping Form

Full Scaffolding

Erection Position

External Scaffolding

Move Method

Integral Lifting Scaffolding

Scaffolding Part Type

Scaffolding Props

Construction Properties

Building Scaffold

Certificate

ISO9001

Steel

Q235/Q355

Finished

Galvanized Ringlock

Delivery Term

45 Days

Container

FCL/LCL

Scaffolding

Building Material

Transport Package

Normal Package

Specification

1800MM

Trademark

OEM/ODM

Origin

China

HS Code

73084000

Production Capacity

500 Ton / Month

Product Description

Steel ladder beam scaffold with adjjustable screw jack for construction building material

Overview

Due to its unique characteristics and intrinsic qualities such as its ease of use or its one-of-a-kind type of strong wedge connection , Safety Step is a versatile scaffolding system that never disappoints its users.

Better productivity

An intelligent and easy -to-use system that requires a minimum of components to be fully functional, enhancing opportunities for increased productivity , Safety Step is a prefect system for straight construction with proven track records in South Korea and Japan.

Improved safety when erected

Safety Step was designed from the beginning with safety in mind , it relies principally on its excellent bond strength and its unique type of strong wedge connection that can cope with the most difficult situations. This strong combination provides greater stability and safety that other systems as the scaffold height increases.

Improved safety in use

In the workplace , employees' safety cannot be overlooked.Safety Step is equipped with boards offering good grip as well as a good locking system for securing difficult weather. Moreover, the ability to see through the boards both up and down prevents working under each other at the same location and contributes to avoid many accidents.

Manufactured to last

All Safety Step components are galvanized and therefore offer excellent anti-corrosion resistance. This protection reduces maintenance costs, extends lifespan and therefore enables longer utilization.

High quality manufacturing

Safety Step is manufactured by experienced an highly trained employees in accordance with ISO 9001 standards. Moreover, in order to guarantee reliability and a top quality finish , all welding are preformed by precision welding robots and the raw material used is thoroughly controlled.

Dimensions

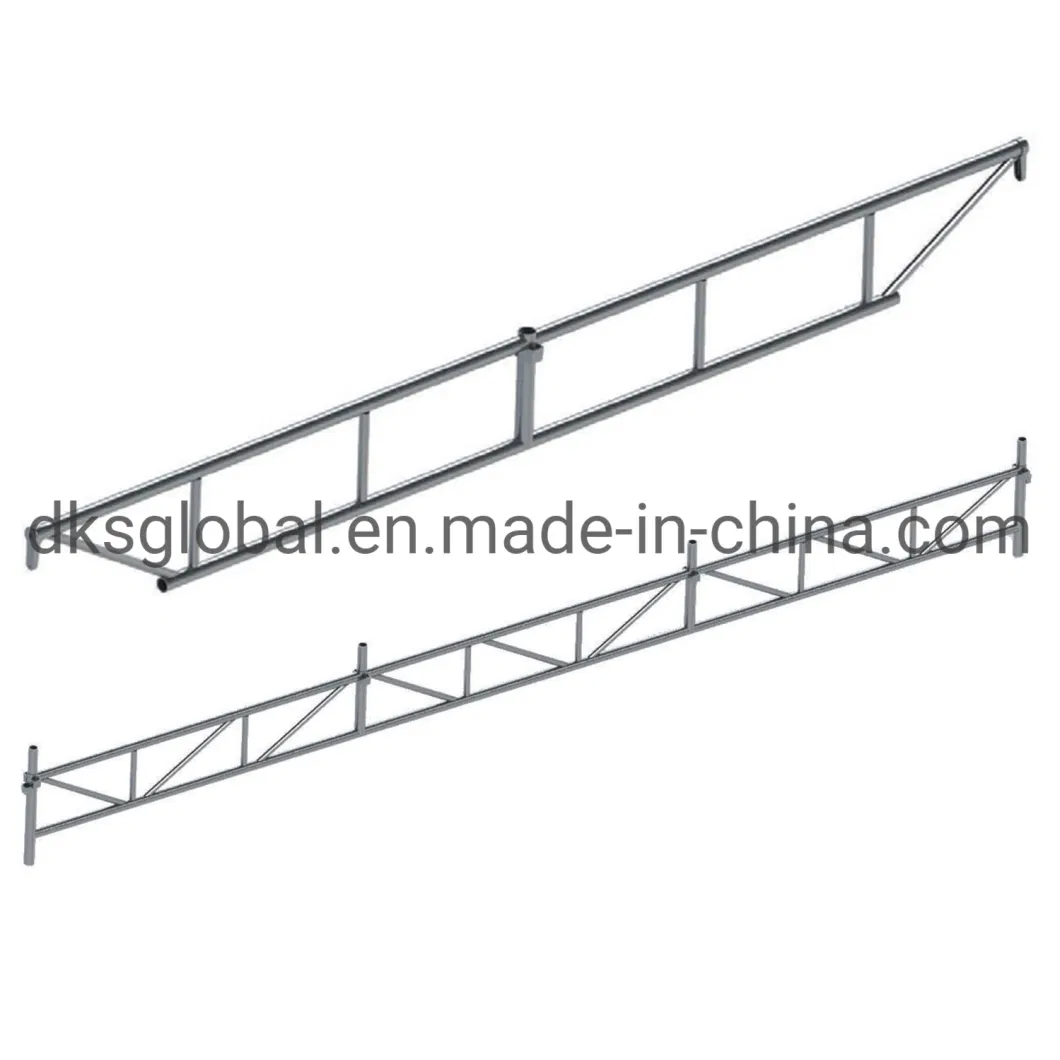

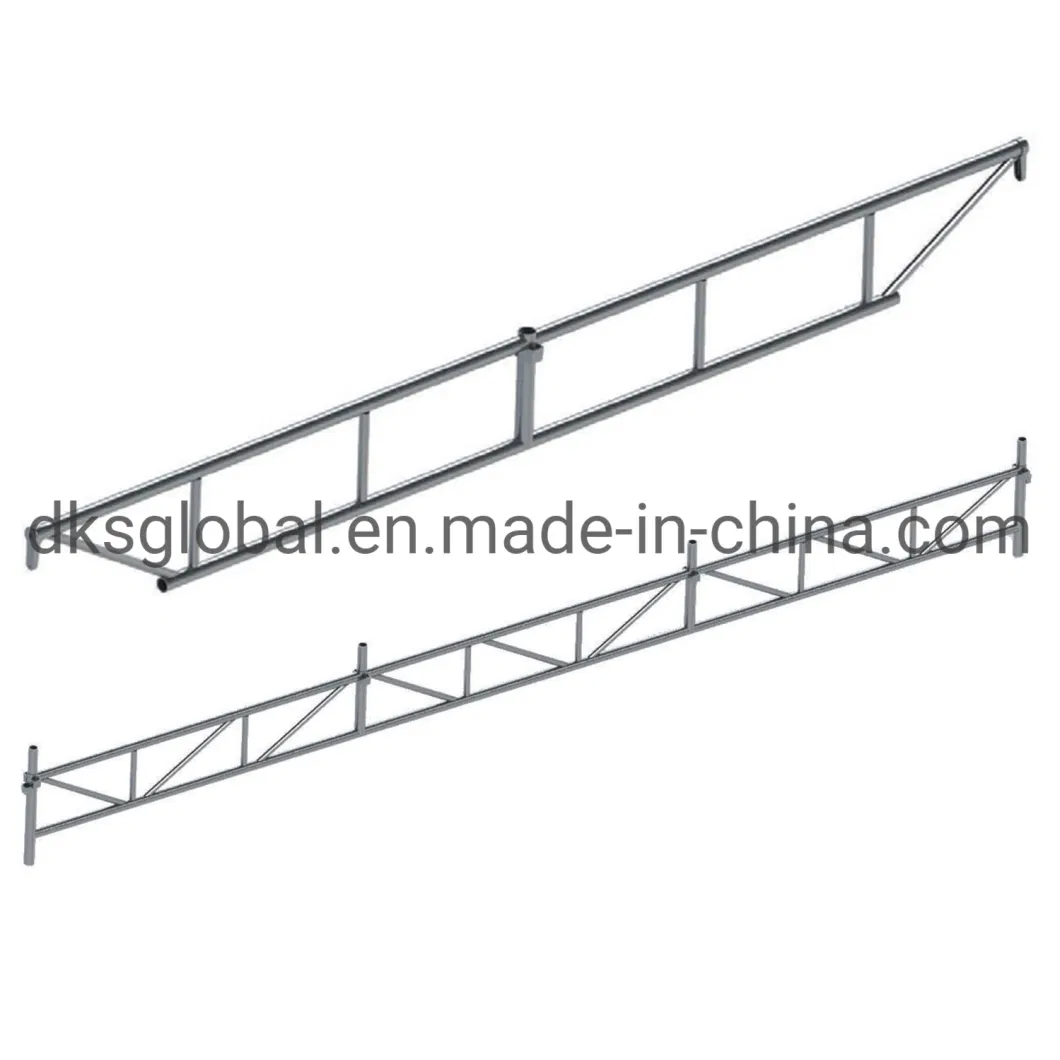

7.Truss

8.Lockpin

9.Brackets

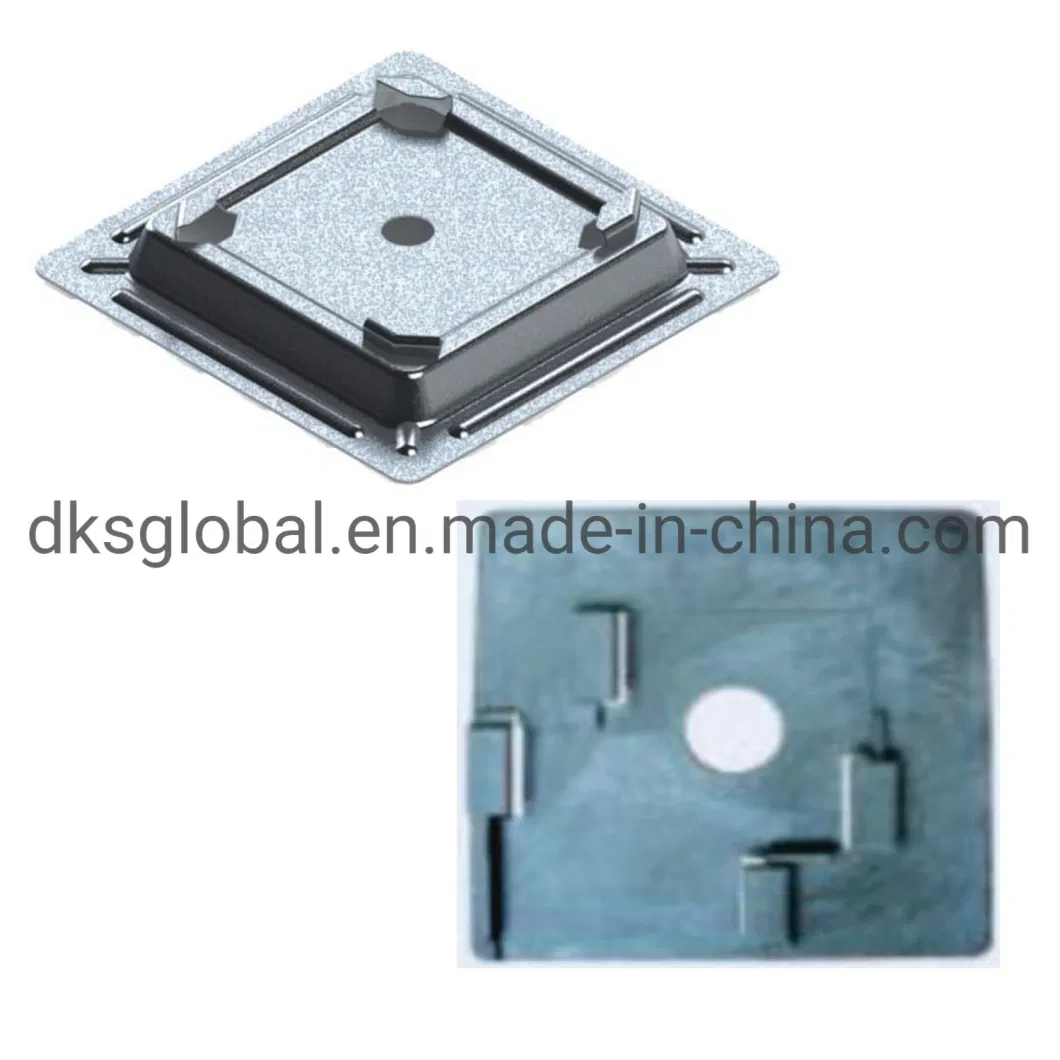

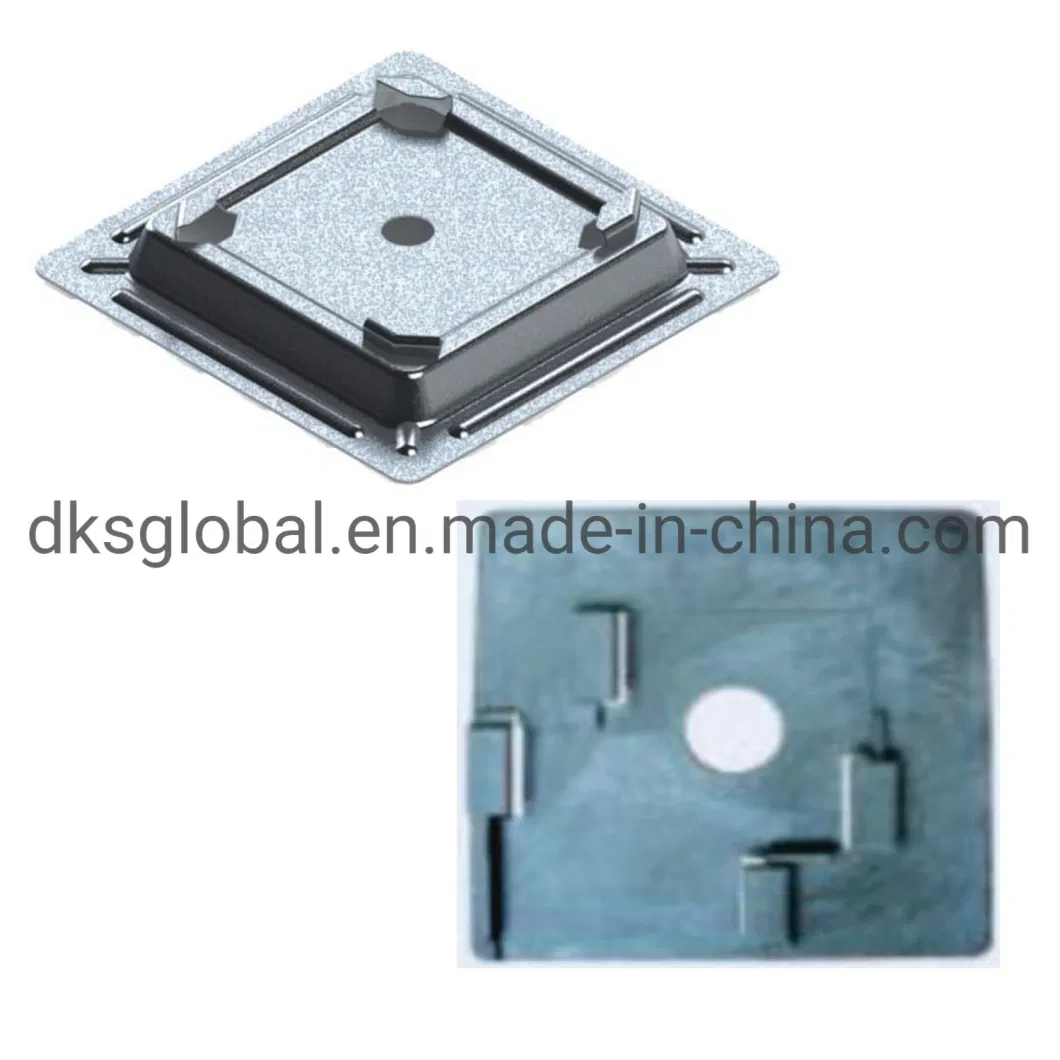

13.Plates

14Wall Connectors

Overview

Due to its unique characteristics and intrinsic qualities such as its ease of use or its one-of-a-kind type of strong wedge connection , Safety Step is a versatile scaffolding system that never disappoints its users.

Better productivity

An intelligent and easy -to-use system that requires a minimum of components to be fully functional, enhancing opportunities for increased productivity , Safety Step is a prefect system for straight construction with proven track records in South Korea and Japan.

Improved safety when erected

Safety Step was designed from the beginning with safety in mind , it relies principally on its excellent bond strength and its unique type of strong wedge connection that can cope with the most difficult situations. This strong combination provides greater stability and safety that other systems as the scaffold height increases.

Improved safety in use

In the workplace , employees' safety cannot be overlooked.Safety Step is equipped with boards offering good grip as well as a good locking system for securing difficult weather. Moreover, the ability to see through the boards both up and down prevents working under each other at the same location and contributes to avoid many accidents.

Manufactured to last

All Safety Step components are galvanized and therefore offer excellent anti-corrosion resistance. This protection reduces maintenance costs, extends lifespan and therefore enables longer utilization.

High quality manufacturing

Safety Step is manufactured by experienced an highly trained employees in accordance with ISO 9001 standards. Moreover, in order to guarantee reliability and a top quality finish , all welding are preformed by precision welding robots and the raw material used is thoroughly controlled.

Dimensions

- Ledgers

| Code | Description | Weight | ||

| DSS-L-1800 | 70.9in | SS Ledger1800mm | 8.8 Ib | 4.0 kg |

| DSS-L-1500 | 59.0in | SS Ledger1500mm | 7.5 Ib | 3.4 kg |

| DSS-L-1200 | 47.2in | SS Ledger1200mm | 5.5 Ib | 2.5 kg |

| DSS-L-0900 | 35.4in | SS Ledger900mm | 4.4 Ib | 2.0 kg |

| DSS-L-0600 | 23.6in | SS Ledger600mm | 3.7 Ib | 1.7 kg |

| DSS-L-0300 | 11.8in | SS Ledger300mm | 2.4 Ib | 1.1 kg |

- Standards

| Code | Description | Weight | ||

| DSS-S-1900 | 74.8in | SS Standard 1900mm | 16.1 Ib | 7.3 kg |

| DSS-S-0950 | 37.4in | SS Standard 950mm | 8.8 Ib | 4.0 kg |

| DSS-S-0475 | 18.7in | SS Standard 475mm | 5.5 Ib | 2.5 kg |

| DSS-S-0130 | 5.1in | SS Standard 130mm | 1.5 Ib | 0.7 kg |

- Brace

| Code | Description | Weight | ||

| DSS-B-2600 | 102.4in | SS Brace 2600mm | 8.2 Ib | 3.7 kg |

| DSS-B-2000 | 78.7in | SS Brace 2000mm | 6.2 Ib | 2.8 kg |

| DSS-B-1500 | 59.1in | SS Brace 1500mm | 5.1 Ib | 2.3 kg |

Planks (400mm Width)

Planks (400mm Width)

| Code | Description | Weight | ||

| DSS-HP-4018 | 70.9in | SS Plank1800mm | 30.9 Ib | 14.0 kg |

| DSS-HP-4015 | 54.0in | SS Plank1500mm | 26.5 Ib | 12.0 kg |

| DSS-HP-4012 | 47.2in | SS Plank1200mm | 22.9 Ib | 10.0 kg |

| DSS-HP-4009 | 35.4in | SS Plank900mm | 18.3 Ib | 18.3 kg |

| DSS-HP-4006 | 23.6in | SS Plank600mm | 13.9 Ib | 13.9 kg |

Planks(240mm width)

Planks(240mm width)

| Code | Description | Weight | ||

| DSS-HP-2418 | 70.4in | SS Plank1800mm | 22.5 Ib | 10.2 kg |

| DSS-HP-2415 | 54.0in | SS Plank1500mm | 18.7 Ib | 8.5 kg |

| DSS-HP-2412 | 47.2in | SS Plank1200mm | 15.9 Ib | 7.2 kg |

| DSS-HP-2409 | 35.4in | SS Plank900mm | 12.1 Ib | 5.5 kg |

| DSS-HP-2406 | 23.6in | SS Plank600mm | 8.4 Ib | 3.8 kg |

- Stairs

| Code | Description | Weight | ||

| [ST]DSS-STAIR | 16.5x 103.0in | 420 x 2615mm | 49.4 Ib | 10.2 kg |

| DSS-HP-2415 | 54.0in | SS Plank1500mm | 18.7 Ib | 8.5 kg |

7.Truss

| Code | Description | Weight | ||

| DSS-T-3600 | 141.7in | SS Truss3600mm | 31.7 Ib | 14.4 kg |

| DSS-T-5400 | 212.6in | SS Truss5400mm | 102.5 Ib | 46.5kg |

8.Lockpin

| Code | Description | Weight | |

| DSS-Lockpin | SS Lockpin | 0.04 Ib | 0.02 kg |

9.Brackets

| Code | Description | Weight | ||

| DSS-MBL-600 | 23.6in | SS Bracket 600mm | 5.3 Ib | 2.4 kg |

| DSS-MBL-350 | 13.8in | SS Bracket 350mm | 3.5 Ib | 1.6 kg |

- Adj.Brackets

| Code | Description | Weight | ||

| DSS-MBLL-600 | 23.6in | SS Adj.Bracket 600mm | 7.5 Ib | 3.4 kg |

| DSS-MBLL-350 | 13.8in | SS Adj.Bracket 350mm | 4.0 Ib | 1.8 kg |

- Jacks

| Code | Description | Weight | ||

| DSS-JF-600 | 23.6in | SS Jack 600mm | 7.3 Ib | 3.3 kg |

| DSS-JF-600 | 8.5in | SS Jack 600mm | 2.0 Ib | 3.5 kg |

- Compress Jacks

| Code | Description | Weight | ||

| DSS-PJ-600 | 23.6in | SS Compress Jack 600mm | 6.6 Ib | 3.0 kg |

| DSS-CJ-215 | 8.5in | SS Compress Jack 215mm | 2.0 Ib | 0.9 kg |

13.Plates

| Code | Description | Weight | ||

| DSS-BP-2424 | 9.4x9.4in | 240x240mm | 1.8 Ib | 0.8 kg |

| DSS-EB-2424 | 9.4x9.4in | 240x240mm | 1.1 Ib | 0.5 kg |

14Wall Connectors

| Code | Description | Weight | ||

| DSS-WC-3352 | 13.0in-20.5in | 330x520mm | 3.3 Ib | 1.5 kg |

| DSS-WC-4872 | 18.9in-28.3in | 480x720mm | 4.0 Ib | 1.8 kg |

ISO Certificate

Factory

DKS was established in 2005, located in Taishan, Guangdong Province, with convenient transportation and only two hours from Guangzhou.

DKS is committed to the production and marketing of scaffolding system, shoring system and formwork system including steel ringlock system, Mega beam, waler beam, shoring jack and others, Also other aluminum scaffolding products.

The factory is also equiped with modern and high-performance production tools and is ISO 9001 certified.

Products including shoring system, scaffolding system, formwork system, and other components for construction site.

And products are exported to Japan, the United States, Canada, Germany, Spain and many other countries.

Factory

DKS was established in 2005, located in Taishan, Guangdong Province, with convenient transportation and only two hours from Guangzhou.

DKS is committed to the production and marketing of scaffolding system, shoring system and formwork system including steel ringlock system, Mega beam, waler beam, shoring jack and others, Also other aluminum scaffolding products.

The factory is also equiped with modern and high-performance production tools and is ISO 9001 certified.

Products including shoring system, scaffolding system, formwork system, and other components for construction site.

And products are exported to Japan, the United States, Canada, Germany, Spain and many other countries.

With ISO9001 and other qualifications, professional R&D and QC team can guanantee the quantity of products.

With ISO9001 and other qualifications, professional R&D and QC team can guanantee the quantity of products. With 15 years of export experience in scaffolding production, DKS products are exported to the United States,USA, Australia, Germany, Japan, Spain and many other countries.

DKS aims to ensure safety in every work site alsong with its mission to bring happiness to its employees and contribute to society.

DKS adhere to the management principles of "quality first, ccustomer first and credit based" since the establishment of the company and always do our best to satisfy potential needs of our customers. DKS is sincerely willing to cooperate with enterprises from all over the world in order to realize a win-win situation since the trend of economic globalization has developed with anirresistible force.

FAQ

FAQ 1. What's your MOQ?

MOQ is required for customized products(30 ton)

2. What's your payment terms?

30% deposit, balance before delivery.

3. What's your delivery time?

It depends on products, 45days to 70days after confirmed the order

4. Where is your factory?

Our company is located in Taishan,Guangdong. Two hours to Guangzhou, shenzhen, four hours to Hongkong.

5. Can we visit your factory?

Of course! Also we can help you to arrange airport pick up and hotel booking.

6. Can you accept OEM/ODM?

Yes, of course!

https://dksglobal.en.made-in-china.com/product-list-1.html

Planks (400mm Width)

Planks (400mm Width) Planks(240mm width)

Planks(240mm width)