Basic Info.

Lapping Form

Full Scaffolding

Erection Position

External Scaffolding

Move Method

Scaffolding

Scaffolding Part Type

Scaffolding Planks

Construction Properties

Building Scaffold

Certificate

ISO9001

Steel

Q235/Q355

Finished

HDG

Delivery Term

45 Days

Container

FCL/LCL

Transport Package

Normal Package

Specification

1800MM

Trademark

OEM/ODM

Origin

China

HS Code

73084000

Production Capacity

500 Ton / Month

Product Description

steel Convinent quialified steel safety step scaffold stairs facede ISO

Overview

Due to its unique characteristics and intrinsic qualities such as its ease of use or its one-of-a-kind type of strong wedge connection , Safety Step is a versatile scaffolding system that never disappoints its users.

Better productivity

An intelligent and easy -to-use system that requires a minimum of components to be fully functional, enhancing opportunities for increased productivity , Safety Step is a prefect system for straight construction with proven track records in South Korea and Japan.

Improved safety when erected

Safety Step was designed from the beginning with safety in mind , it relies principally on its excellent bond strength and its unique type of strong wedge connection that can cope with the most difficult situations. This strong combination provides greater stability and safety that other systems as the scaffold height increases.

Improved safety in use

In the workplace , employees' safety cannot be overlooked.Safety Step is equipped with boards offering good grip as well as a good locking system for securing difficult weather. Moreover, the ability to see through the boards both up and down prevents working under each other at the same location and contributes to avoid many accidents.

Manufactured to last

All Safety Step components are galvanized and therefore offer excellent anti-corrosion resistance. This protection reduces maintenance costs, extends lifespan and therefore enables longer utilization.

High quality manufacturing

Safety Step is manufactured by experienced an highly trained employees in accordance with ISO 9001 standards. Moreover, in order to guarantee reliability and a top quality finish , all welding are preformed by precision welding robots and the raw material used is thoroughly controlled.

Dimensions

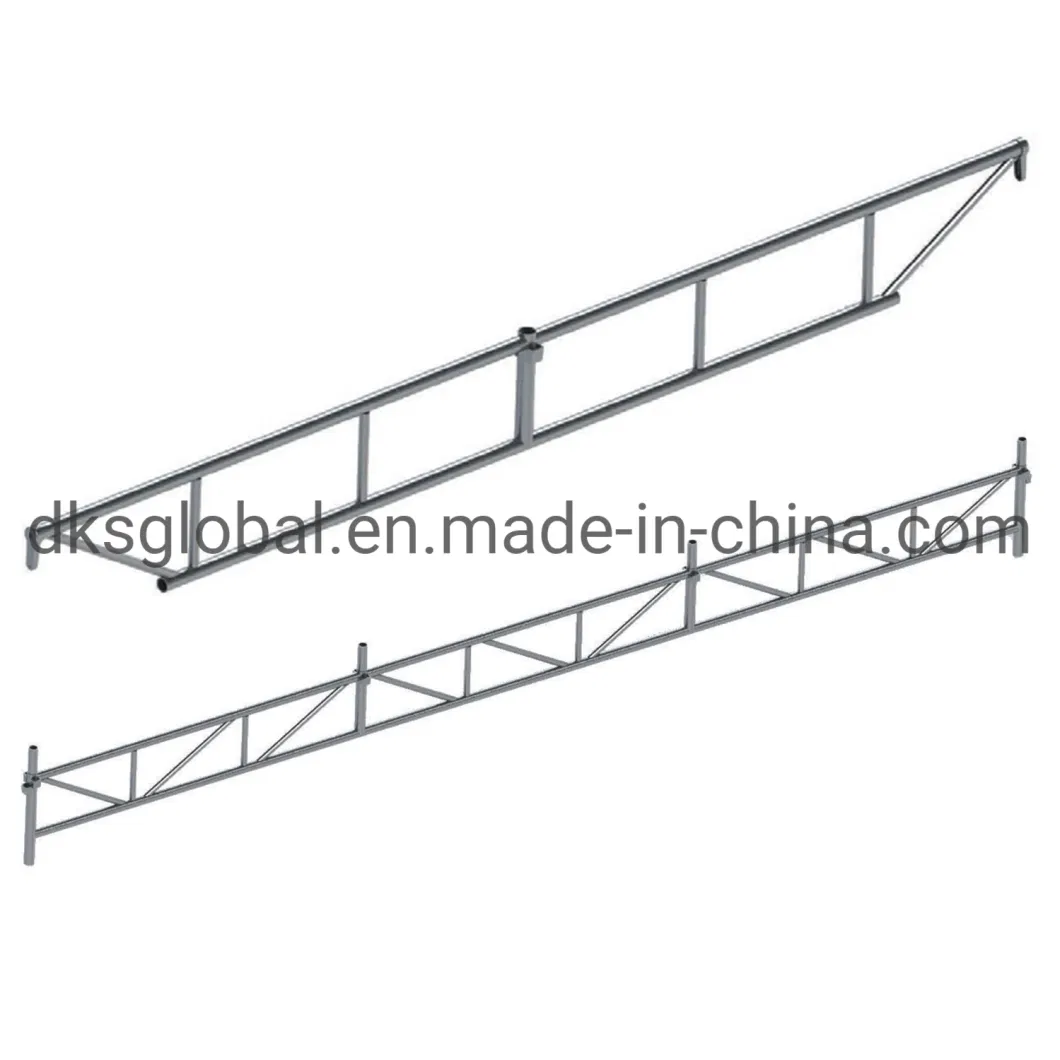

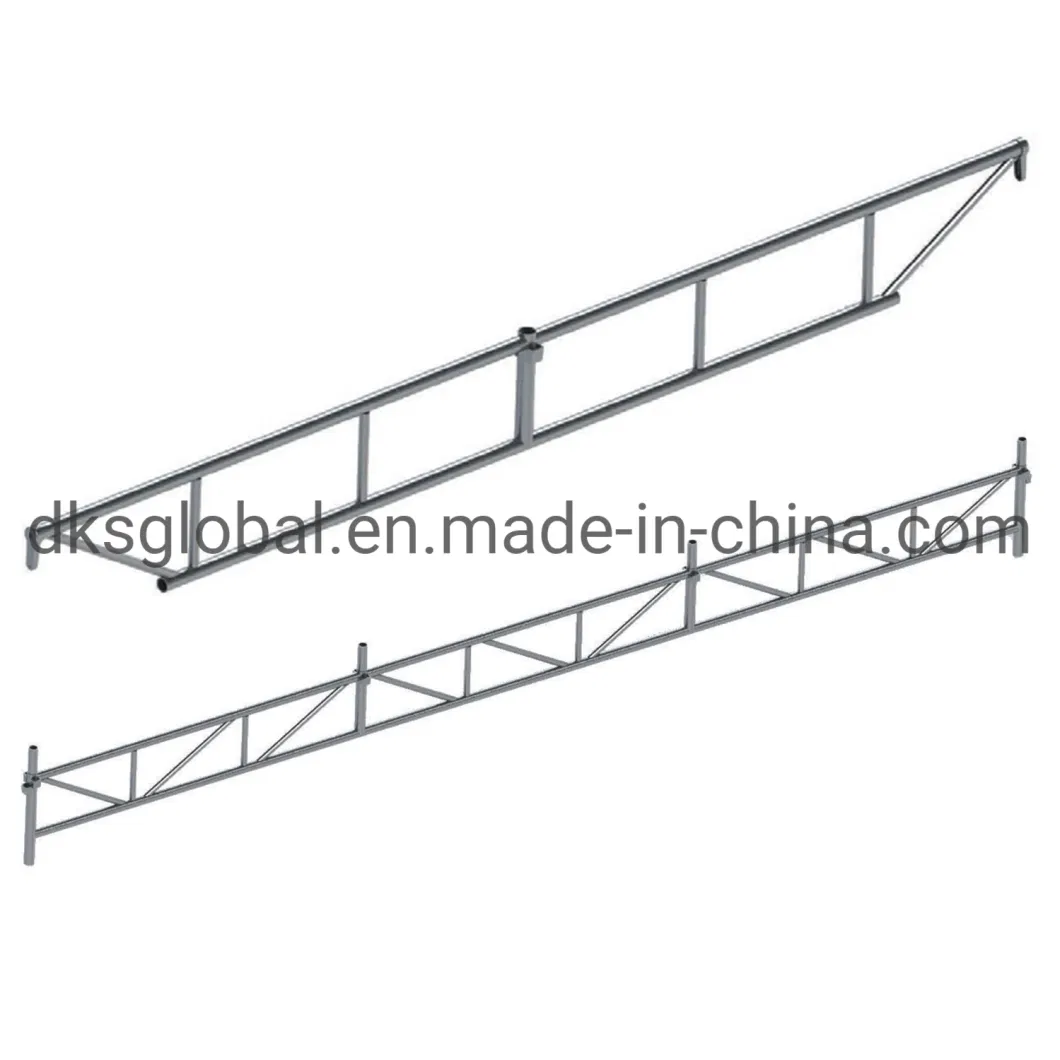

7.Truss

8.Lockpin

9.Brackets

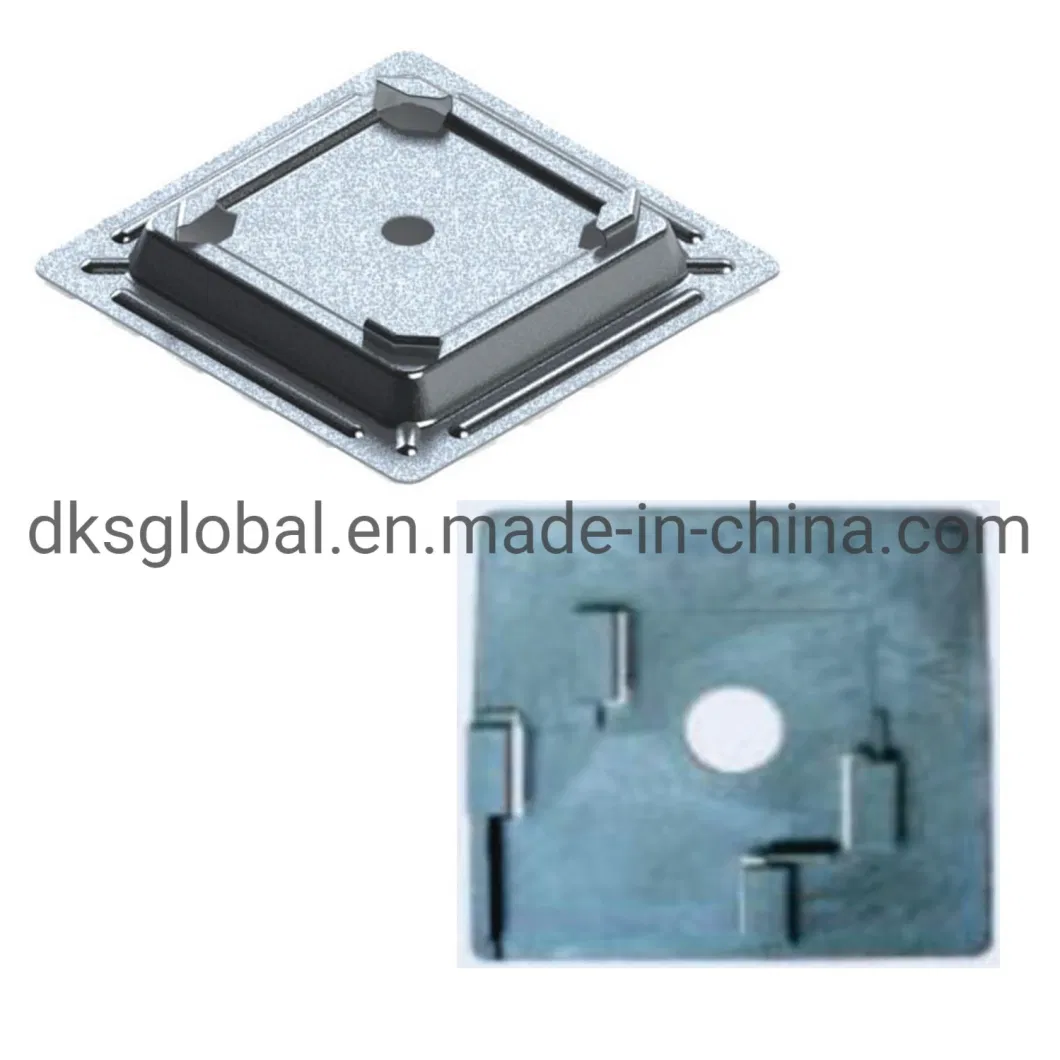

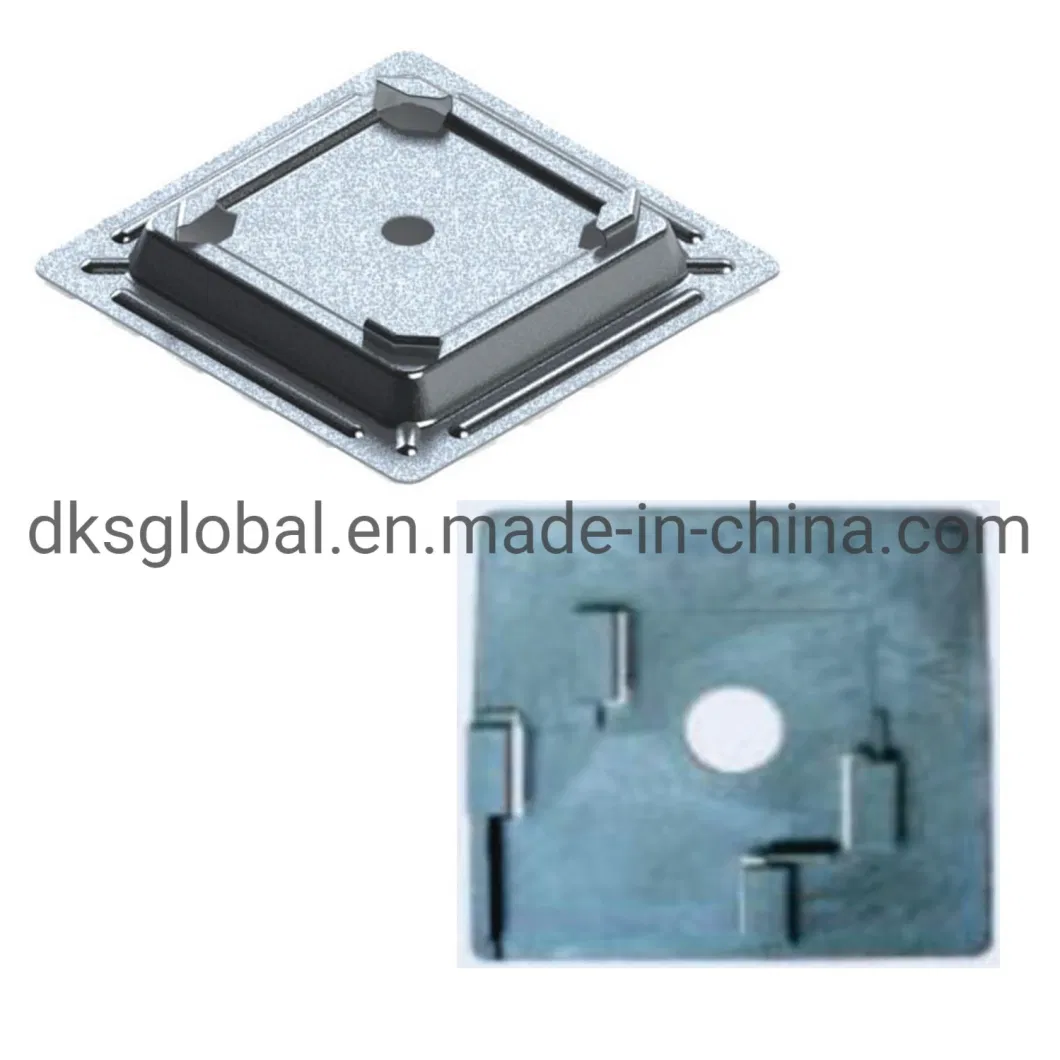

13.Plates

14Wall Connectors

Overview

Due to its unique characteristics and intrinsic qualities such as its ease of use or its one-of-a-kind type of strong wedge connection , Safety Step is a versatile scaffolding system that never disappoints its users.

Better productivity

An intelligent and easy -to-use system that requires a minimum of components to be fully functional, enhancing opportunities for increased productivity , Safety Step is a prefect system for straight construction with proven track records in South Korea and Japan.

Improved safety when erected

Safety Step was designed from the beginning with safety in mind , it relies principally on its excellent bond strength and its unique type of strong wedge connection that can cope with the most difficult situations. This strong combination provides greater stability and safety that other systems as the scaffold height increases.

Improved safety in use

In the workplace , employees' safety cannot be overlooked.Safety Step is equipped with boards offering good grip as well as a good locking system for securing difficult weather. Moreover, the ability to see through the boards both up and down prevents working under each other at the same location and contributes to avoid many accidents.

Manufactured to last

All Safety Step components are galvanized and therefore offer excellent anti-corrosion resistance. This protection reduces maintenance costs, extends lifespan and therefore enables longer utilization.

High quality manufacturing

Safety Step is manufactured by experienced an highly trained employees in accordance with ISO 9001 standards. Moreover, in order to guarantee reliability and a top quality finish , all welding are preformed by precision welding robots and the raw material used is thoroughly controlled.

Dimensions

- Ledgers

| Code | Description | Weight | ||

| DSS-L-1800 | 70.9in | SS Ledger1800mm | 8.8 Ib | 4.0 kg |

| DSS-L-1500 | 59.0in | SS Ledger1500mm | 7.5 Ib | 3.4 kg |

| DSS-L-1200 | 47.2in | SS Ledger1200mm | 5.5 Ib | 2.5 kg |

| DSS-L-0900 | 35.4in | SS Ledger900mm | 4.4 Ib | 2.0 kg |

| DSS-L-0600 | 23.6in | SS Ledger600mm | 3.7 Ib | 1.7 kg |

| DSS-L-0300 | 11.8in | SS Ledger300mm | 2.4 Ib | 1.1 kg |

- Standards

| Code | Description | Weight | ||

| DSS-S-1900 | 74.8in | SS Standard 1900mm | 16.1 Ib | 7.3 kg |

| DSS-S-0950 | 37.4in | SS Standard 950mm | 8.8 Ib | 4.0 kg |

| DSS-S-0475 | 18.7in | SS Standard 475mm | 5.5 Ib | 2.5 kg |

| DSS-S-0130 | 5.1in | SS Standard 130mm | 1.5 Ib | 0.7 kg |

- Brace

| Code | Description | Weight | ||

| DSS-B-2600 | 102.4in | SS Brace 2600mm | 8.2 Ib | 3.7 kg |

| DSS-B-2000 | 78.7in | SS Brace 2000mm | 6.2 Ib | 2.8 kg |

| DSS-B-1500 | 59.1in | SS Brace 1500mm | 5.1 Ib | 2.3 kg |

Planks (400mm Width)

Planks (400mm Width)

| Code | Description | Weight | ||

| DSS-HP-4018 | 70.9in | SS Plank1800mm | 30.9 Ib | 14.0 kg |

| DSS-HP-4015 | 54.0in | SS Plank1500mm | 26.5 Ib | 12.0 kg |

| DSS-HP-4012 | 47.2in | SS Plank1200mm | 22.9 Ib | 10.0 kg |

| DSS-HP-4009 | 35.4in | SS Plank900mm | 18.3 Ib | 18.3 kg |

| DSS-HP-4006 | 23.6in | SS Plank600mm | 13.9 Ib | 13.9 kg |

Planks(240mm width)

Planks(240mm width)

| Code | Description | Weight | ||

| DSS-HP-2418 | 70.4in | SS Plank1800mm | 22.5 Ib | 10.2 kg |

| DSS-HP-2415 | 54.0in | SS Plank1500mm | 18.7 Ib | 8.5 kg |

| DSS-HP-2412 | 47.2in | SS Plank1200mm | 15.9 Ib | 7.2 kg |

| DSS-HP-2409 | 35.4in | SS Plank900mm | 12.1 Ib | 5.5 kg |

| DSS-HP-2406 | 23.6in | SS Plank600mm | 8.4 Ib | 3.8 kg |

- Stairs

| Code | Description | Weight | ||

| [ST]DSS-STAIR | 16.5x 103.0in | 420 x 2615mm | 49.4 Ib | 10.2 kg |

| DSS-HP-2415 | 54.0in | SS Plank1500mm | 18.7 Ib | 8.5 kg |

7.Truss

| Code | Description | Weight | ||

| DSS-T-3600 | 141.7in | SS Truss3600mm | 31.7 Ib | 14.4 kg |

| DSS-T-5400 | 212.6in | SS Truss5400mm | 102.5 Ib | 46.5kg |

8.Lockpin

| Code | Description | Weight | |

| DSS-Lockpin | SS Lockpin | 0.04 Ib | 0.02 kg |

9.Brackets

| Code | Description | Weight | ||

| DSS-MBL-600 | 23.6in | SS Bracket 600mm | 5.3 Ib | 2.4 kg |

| DSS-MBL-350 | 13.8in | SS Bracket 350mm | 3.5 Ib | 1.6 kg |

- Adj.Brackets

| Code | Description | Weight | ||

| DSS-MBLL-600 | 23.6in | SS Adj.Bracket 600mm | 7.5 Ib | 3.4 kg |

| DSS-MBLL-350 | 13.8in | SS Adj.Bracket 350mm | 4.0 Ib | 1.8 kg |

- Jacks

| Code | Description | Weight | ||

| DSS-JF-600 | 23.6in | SS Jack 600mm | 7.3 Ib | 3.3 kg |

| DSS-JF-600 | 8.5in | SS Jack 600mm | 2.0 Ib | 3.5 kg |

- Compress Jacks

| Code | Description | Weight | ||

| DSS-PJ-600 | 23.6in | SS Compress Jack 600mm | 6.6 Ib | 3.0 kg |

| DSS-CJ-215 | 8.5in | SS Compress Jack 215mm | 2.0 Ib | 0.9 kg |

13.Plates

| Code | Description | Weight | ||

| DSS-BP-2424 | 9.4x9.4in | 240x240mm | 1.8 Ib | 0.8 kg |

| DSS-EB-2424 | 9.4x9.4in | 240x240mm | 1.1 Ib | 0.5 kg |

14Wall Connectors

| Code | Description | Weight | ||

| DSS-WC-3352 | 13.0in-20.5in | 330x520mm | 3.3 Ib | 1.5 kg |

| DSS-WC-4872 | 18.9in-28.3in | 480x720mm | 4.0 Ib | 1.8 kg |

Factory

Located in Guangdong, the factory cover an area of 16,528 M2 and is specialized in the production of shoring and safety systems.

The factory is also equiped with modern and high-performance production tools and is ISO 9001 certified.

Products including shoring system, scaffolding system, formwork system, and other components for construction site.

And products are exported to Japan, the United States, Canada, Germany, Spain and many other countries.

Planks (400mm Width)

Planks (400mm Width) Planks(240mm width)

Planks(240mm width)