Basic Info.

Model NO.

scaffold

Erection Position

External Scaffolding

Move Method

as Customer Work Need

Scaffolding Part Type

Scaffolding Frames

Construction Properties

Building Scaffold

Surface Finished

Hot Dipped Galvanization

Certificate

ISO, Ce, SGS

Transport Package

Steel Rack

Specification

500mm, 1000, 1500mm, 2000mm, 2500mm, 3000mm, 4000

Trademark

HongDe RuiLin

Origin

China

HS Code

73084000

Production Capacity

500 Tons /Day

Product Description

HongDe Ruilin Steel Material Quick Use Ringlock Scaffolding Stage Scaffold

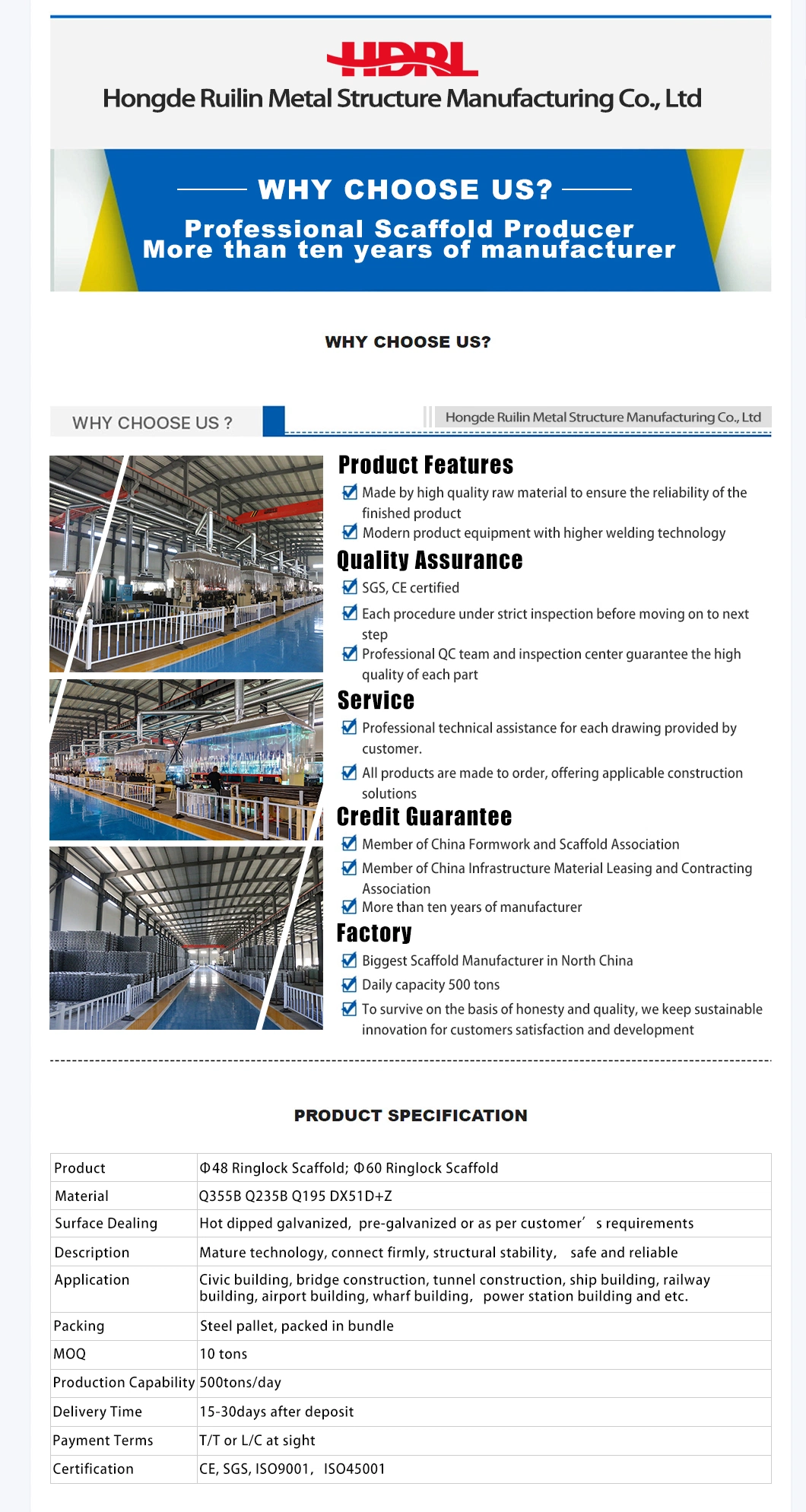

HDRL Scaffold produces various ringlock scaffolding, such as Germany layher allround scaffolding types, USA type scaffolding, New Zealand Types of Ringlock Scaffolding and Spanish type multidirectional scaffolding, etc. All types of ringlock scaffolding are made from OD48.3mm scaffold tube and OD60.3mm scaffold tube for shoring heavy duty.

Ringlock scaffold is one of the most advanced and popular type scaffold systems in the world. As a modular scaffold system, according to customer requirement, it is extremely versatile and can be erected from the ground up or suspended. Ringlock scaffolding can also be erected in a stationary or rolling tower configuration, which makes it perfect for safe work at height.

Features of HongDe RuiLin Steel Material Quick Use Ringlock Scaffolding Stage Scaffold :

1) Perfect technology

It is an international mainstream scaffolding connection method. Reasonable node design can achieve the transmission of each member through the node center. It is widely used in European and American countries and regions. It is an upgraded product of scaffolding. It has mature technology, solid connection, stable structure, safe and reliable .

2) Raw material upgrade

The main raw materials are all made of low-alloy structural steel (national standard Q355B), which is twice as strong as ordinary steel pipes for traditional scaffolding.

3) Hot dipped galvanizing process

The main components are made of internal and external hot-dip galvanized anti-corrosion technology, which not only improves the service life of the product, but also provides a further guarantee for safety, and at the same time, it is beautiful and beautiful.

4) Reliable quality

The product starts from cutting, the entire product processing has to go through 20 processes, each process is processed with a special machine, reducing the intervention of human factors, especially the production of crossbars and vertical rods, and the use of fully automatic welding special machines has achieved the product High precision, strong interchangeability, stable and reliable quality.

5) Large carrying capacity

The vertical standard connection is a concentric socket, and the joint is in the plane of the frame. The joint is resistant to bending, shearing and torsion.

Taking the 60 series as an example, the allowable load of a single pole with a height of 5 meters is 9.5 tons (safety factor is 2), and the breaking load is 19 tons, which is 3 times that of traditional products.

6) Less consumption, light weight, less maintenance, convenient transportation and easy storage.

Under normal circumstances, the spacing of the poles is 1.5m, 1.8m, the spacing of the crossbars is 1.5m, the large spacing can reach 3m, and the step distance is 2m, so the amount of the same support volume avoids the traditional products by 1/2, weight Will reduce 1/2, 1/3. Crossbar can be removed and turn around, saving time and materials.

7) Fast assembly, convenient use, cost saving and high efficiency.

Due to the small amount and light weight, the operator can assemble more conveniently. The disassembly, transportation, rental, and maintenance costs will be saved accordingly. At the same time, the loss of loose fasteners is avoided. The assembly and disassembly speed of the joint is more than 5 times faster than that of the ordinary bowl buckle scaffolding. The assembly and disassembly use less manpower, and the worker can complete it with an iron hammer.

8) Long life

The service life is much longer than that of ordinary scaffolding, and it can generally be used for more than ten years. Since the bolt connection is abandoned, the components are resistant to bumps and knocks, even if they are corroded, they will not affect the use of disassembly.

9) High security

The joint design considers the effect of self-gravity, so that the joint has a reliable two-way self-locking function, and the load acting on the crossbar is transmitted to the upright rod through the disk buckle, which has strong shear resistance.

10) Versatility function

According to the construction requirements on site, single and double row scaffolds, support frames, support columns and other multi-functional construction equipment with different rental frame sizes, shapes and carrying capacities can be formed.

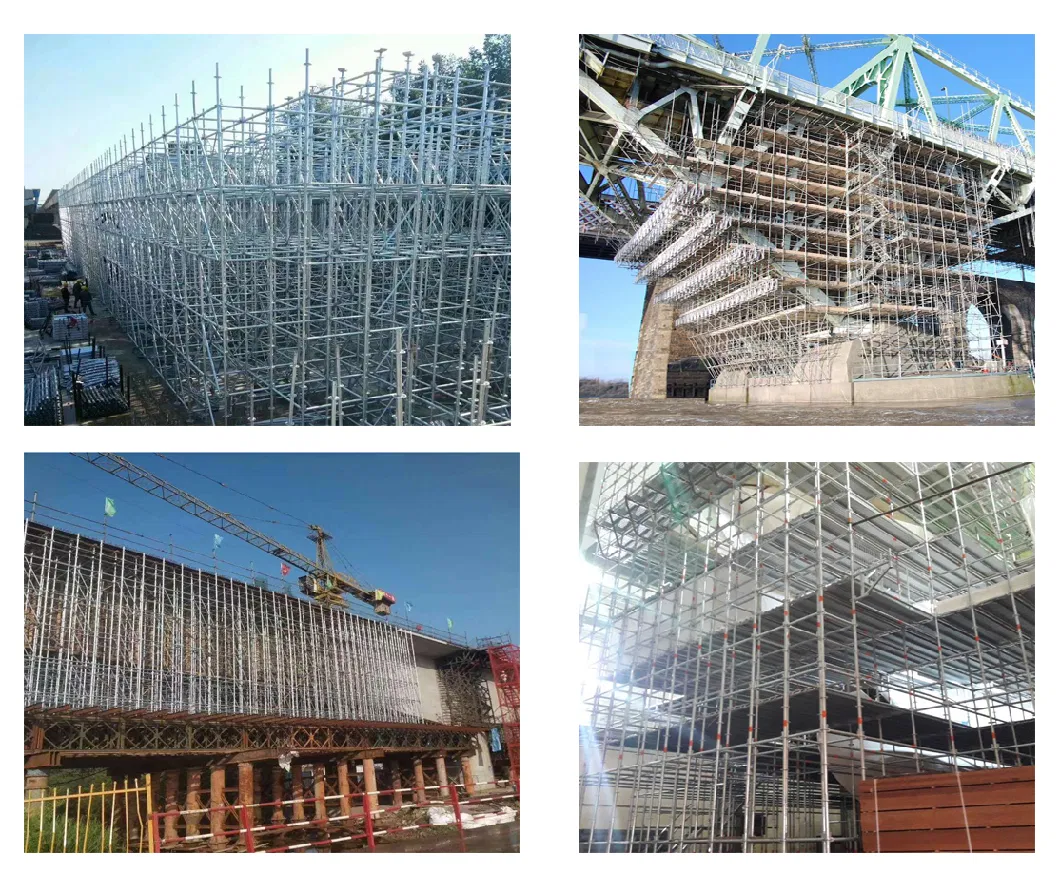

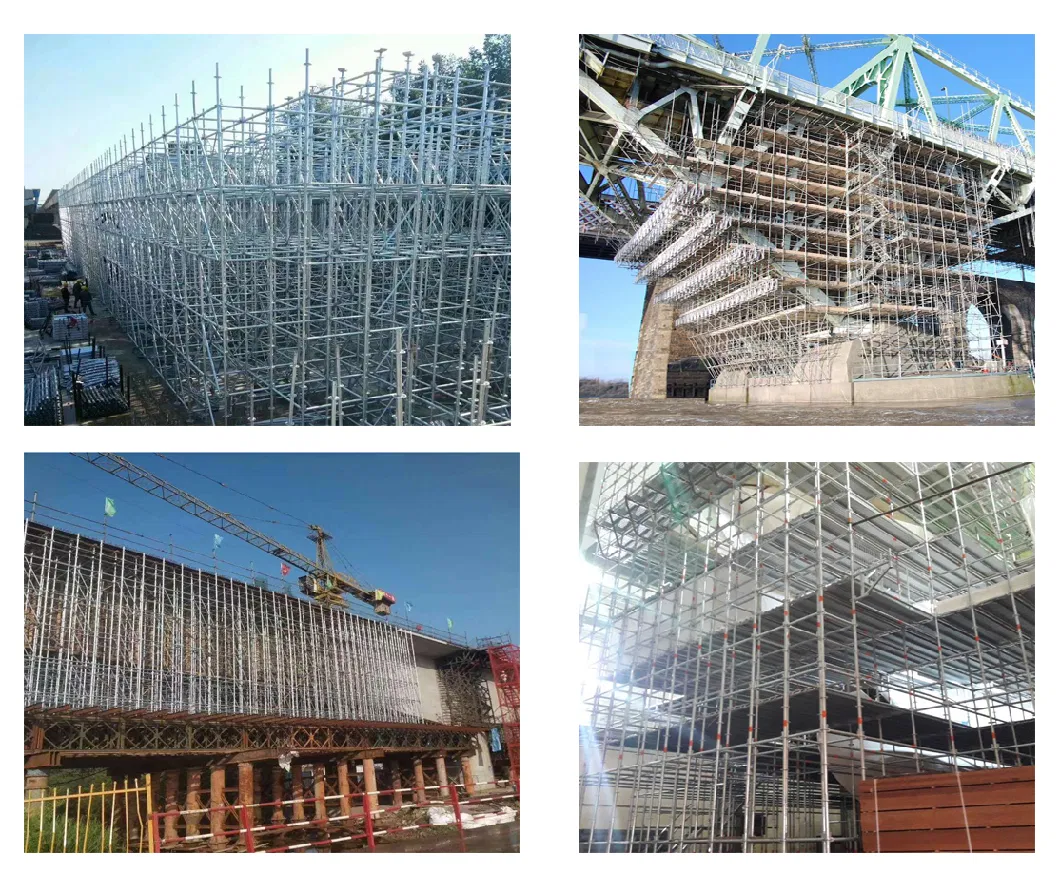

Construction samples with Steel Material Quick Use Ringlock Scaffolding Stage Scaffold

Models of HongDe RuiLin High Quality of Steel Material Quick Use Ringlock Scaffolding Stage Scaffold

More parts and details if needed, please just feel free to contact with us, we will try our best to satisfy your requirement, for Steel Material Quick Use Ringlock Scaffolding Stage Scaffold

Components for High Quality of Steel Pedal for Steel Material Quick Use Ringlock Scaffolding Stage Scaffold

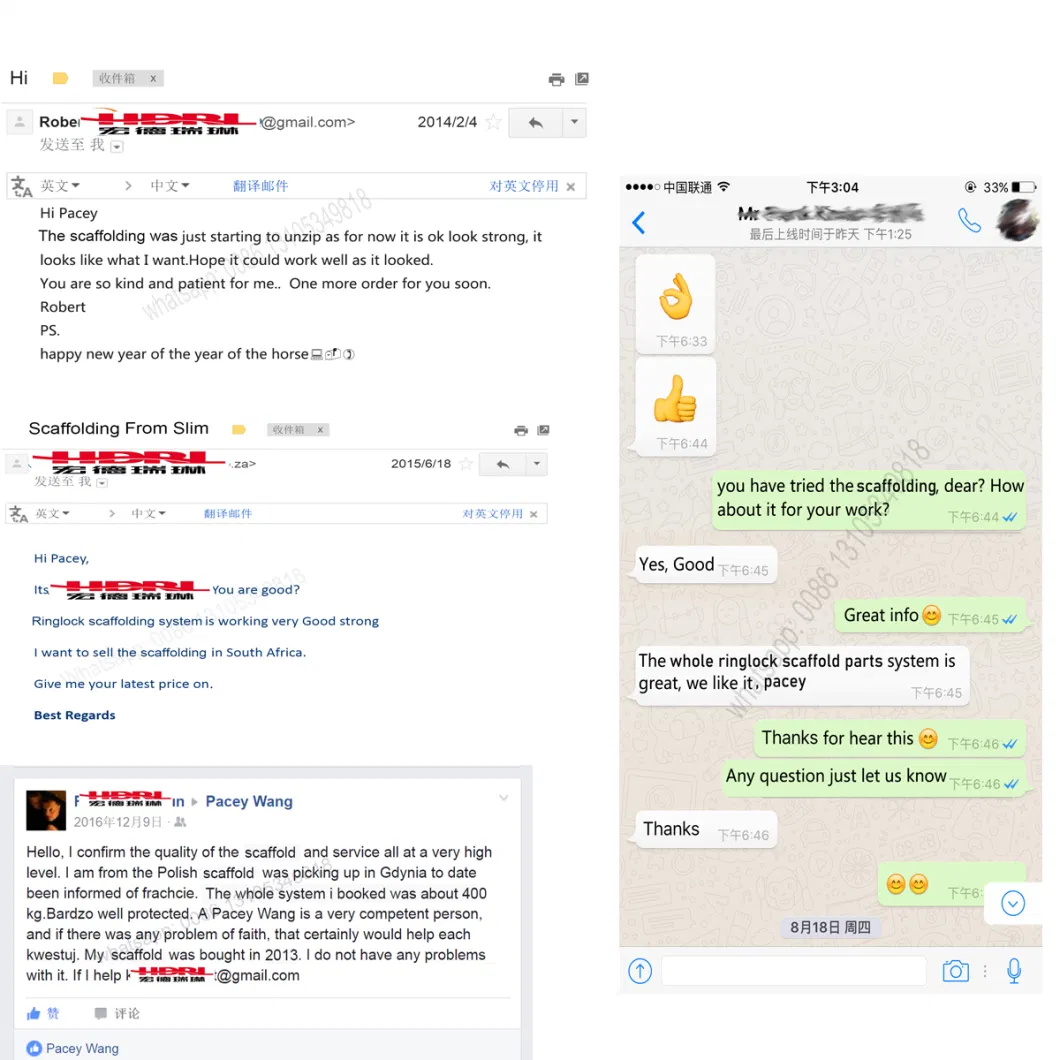

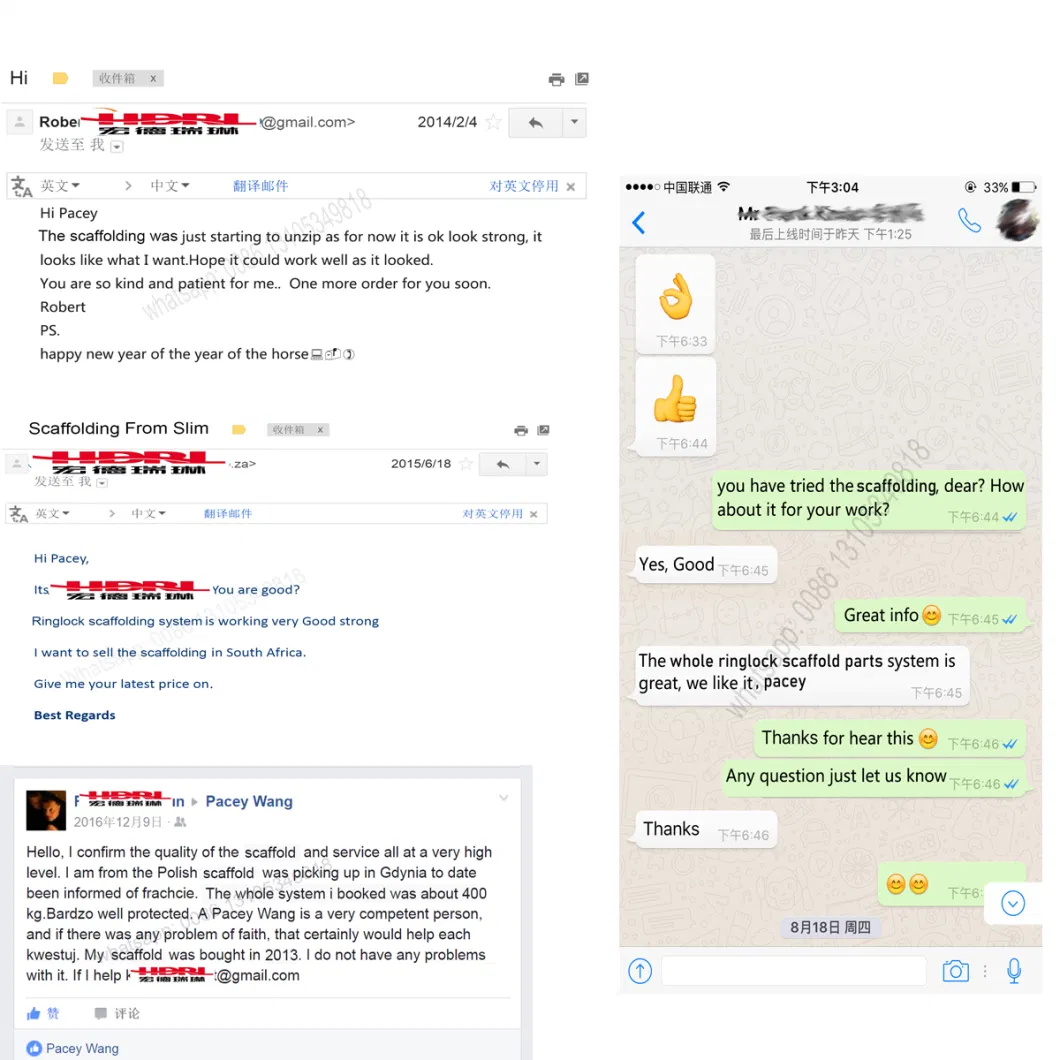

Customer feedback for ShanDong manufacturer High Quality of Steel Material Quick Use Ringlock Scaffolding Stage Scaffold

Shippment of Germany type Steel Construction Steel Pedal for Steel Material Quick Use Ringlock Scaffolding Stage Scaffold

Certificate Germany type High Quality of Steel Pedal for Steel Material Quick Use Ringlock Scaffolding Stage Scaffold

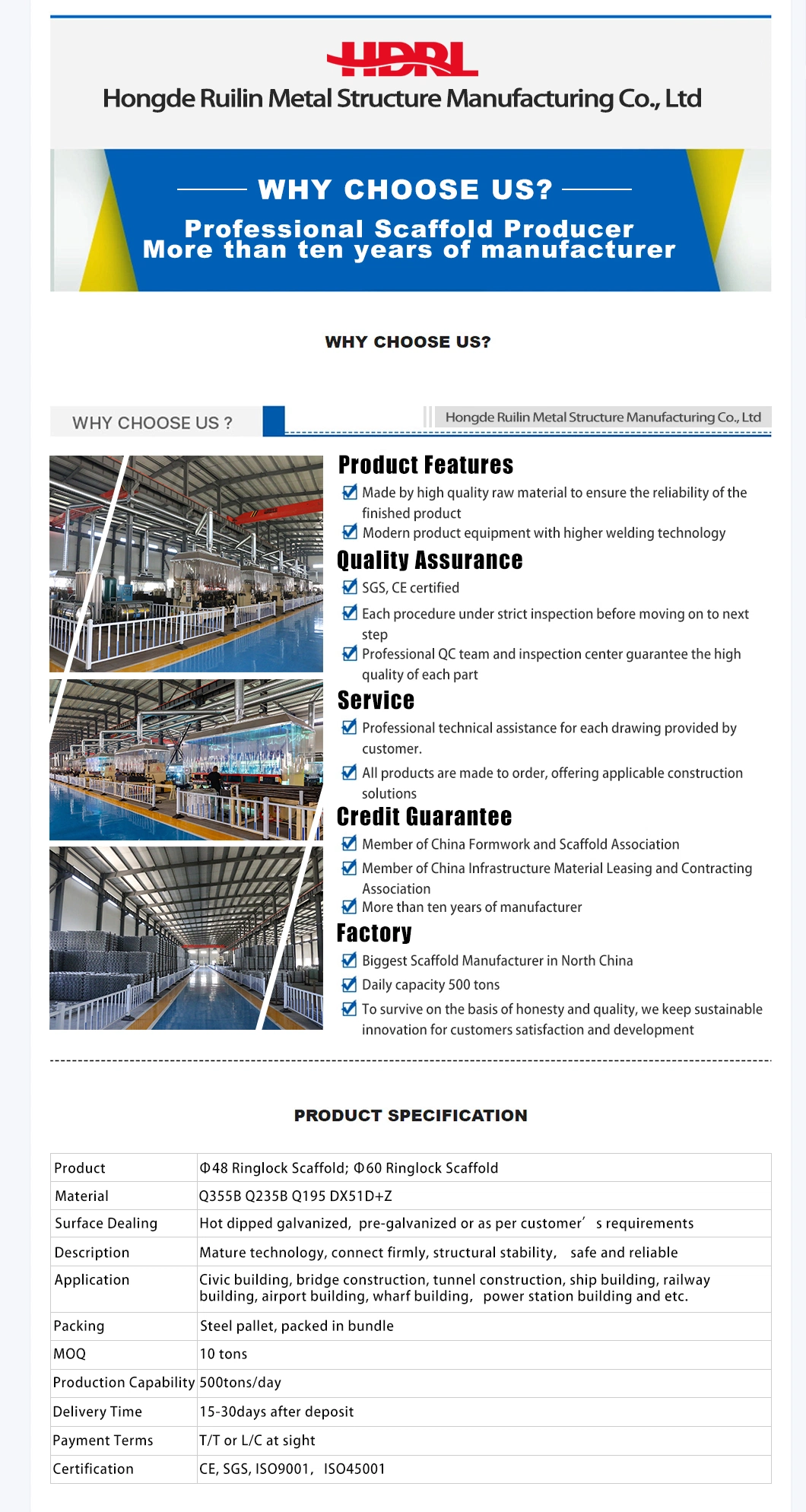

Best quality China ShanDong manufacturer Steel Pedal for Steel Material Quick Use Ringlock Scaffolding Stage Scaffold

HDRL Scaffold produces various ringlock scaffolding, such as Germany layher allround scaffolding types, USA type scaffolding, New Zealand Types of Ringlock Scaffolding and Spanish type multidirectional scaffolding, etc. All types of ringlock scaffolding are made from OD48.3mm scaffold tube and OD60.3mm scaffold tube for shoring heavy duty.

Ringlock scaffold is one of the most advanced and popular type scaffold systems in the world. As a modular scaffold system, according to customer requirement, it is extremely versatile and can be erected from the ground up or suspended. Ringlock scaffolding can also be erected in a stationary or rolling tower configuration, which makes it perfect for safe work at height.

Features of HongDe RuiLin Steel Material Quick Use Ringlock Scaffolding Stage Scaffold :

1) Perfect technology

It is an international mainstream scaffolding connection method. Reasonable node design can achieve the transmission of each member through the node center. It is widely used in European and American countries and regions. It is an upgraded product of scaffolding. It has mature technology, solid connection, stable structure, safe and reliable .

2) Raw material upgrade

The main raw materials are all made of low-alloy structural steel (national standard Q355B), which is twice as strong as ordinary steel pipes for traditional scaffolding.

3) Hot dipped galvanizing process

The main components are made of internal and external hot-dip galvanized anti-corrosion technology, which not only improves the service life of the product, but also provides a further guarantee for safety, and at the same time, it is beautiful and beautiful.

4) Reliable quality

The product starts from cutting, the entire product processing has to go through 20 processes, each process is processed with a special machine, reducing the intervention of human factors, especially the production of crossbars and vertical rods, and the use of fully automatic welding special machines has achieved the product High precision, strong interchangeability, stable and reliable quality.

5) Large carrying capacity

The vertical standard connection is a concentric socket, and the joint is in the plane of the frame. The joint is resistant to bending, shearing and torsion.

Taking the 60 series as an example, the allowable load of a single pole with a height of 5 meters is 9.5 tons (safety factor is 2), and the breaking load is 19 tons, which is 3 times that of traditional products.

6) Less consumption, light weight, less maintenance, convenient transportation and easy storage.

Under normal circumstances, the spacing of the poles is 1.5m, 1.8m, the spacing of the crossbars is 1.5m, the large spacing can reach 3m, and the step distance is 2m, so the amount of the same support volume avoids the traditional products by 1/2, weight Will reduce 1/2, 1/3. Crossbar can be removed and turn around, saving time and materials.

7) Fast assembly, convenient use, cost saving and high efficiency.

Due to the small amount and light weight, the operator can assemble more conveniently. The disassembly, transportation, rental, and maintenance costs will be saved accordingly. At the same time, the loss of loose fasteners is avoided. The assembly and disassembly speed of the joint is more than 5 times faster than that of the ordinary bowl buckle scaffolding. The assembly and disassembly use less manpower, and the worker can complete it with an iron hammer.

8) Long life

The service life is much longer than that of ordinary scaffolding, and it can generally be used for more than ten years. Since the bolt connection is abandoned, the components are resistant to bumps and knocks, even if they are corroded, they will not affect the use of disassembly.

9) High security

The joint design considers the effect of self-gravity, so that the joint has a reliable two-way self-locking function, and the load acting on the crossbar is transmitted to the upright rod through the disk buckle, which has strong shear resistance.

10) Versatility function

According to the construction requirements on site, single and double row scaffolds, support frames, support columns and other multi-functional construction equipment with different rental frame sizes, shapes and carrying capacities can be formed.

Construction samples with Steel Material Quick Use Ringlock Scaffolding Stage Scaffold

Models of HongDe RuiLin High Quality of Steel Material Quick Use Ringlock Scaffolding Stage Scaffold

| Vertical standard | ||||

| Name | Model | Size (mm) | Weight (kg) | Materials |

| 60 model vertical standard | A-LG-500 | Ф60*3.25*500 | 4.1 | Q355B |

| A-LG-1000 | Ф60*3.25*1000 | 6.94 | Q355B | |

| A-LG-1500 | Ф60*3.25*1500 | 9.75 | Q355B | |

| A-LG-2000 | Ф60*3.25*2000 | 12.61 | Q355B | |

| A-LG-2500 | Ф60*3.25*2500 | 15.4 | Q355B | |

| A-LG-3000 | Ф60*3.25*3000 | 18.23 | Q355B | |

| 48 model vertical standard | B-LG-500 | Ф48*3.25*500 | 3.36 | Q355B |

| B-LG-1000 | Ф48*3.25*1000 | 5.75 | Q355B | |

| B-LG-1500 | Ф48*3.25*1500 | 8.08 | Q355B | |

| B-LG-2000 | Ф48*3.25*2000 | 10.3 | Q355B | |

| B-LG-2500 | Ф48*3.25*2500 | 12.46 | Q355B | |

| B-LG-3000 | Ф48*3.25*3000 | 14.73 | Q355B | |

| Horizontal ledger | ||||

| Name | Model | Size (mm) | Weight (kg) | Materials |

| 60 model Horizontal ledger | A-LG-300 | Ф48*2.75*240 | 1.33 | Q235B |

| A-LG-600 | Ф48*2.75*540 | 2.07 | Q235B | |

| A-LG-900 | Ф48*2.75*840 | 3.03 | Q235B | |

| A-LG-1200 | Ф48*2.75*1140 | 3.99 | Q235B | |

| A-LG-1500 | Ф48*2.75*1440 | 4.95 | Q235B | |

| A-LG-1800 | Ф48*2.75*1740 | 5.93 | Q235B | |

| A-LG-2100 | Ф48*2.75*2040 | 6.55 | Q235B | |

| 48 model Horizontal ledger | B-LG-300 | Ф38*2.75*252 | 1.37 | Q235B |

| B-LG-600 | Ф48*2.75*552 | 2.11 | Q235B | |

| B-LG-900 | Ф48*2.75*852 | 3.06 | Q235B | |

| B-LG-1200 | Ф48*2.75*1152 | 4.02 | Q235B | |

| B-LG-1500 | Ф48*2.75*1452 | 4.98 | Q235B | |

| B-LG-1800 | Ф48*2.75*1752 | 5.97 | Q235B | |

| B-LG-2100 | Ф48*2.75*2052 | 6.58 | Q235B | |

| Diagonal Brace | ||||

| Name | Model | Size (mm) | Weight (kg) | Materials |

| 60 model Diagonal Brace | A-XG-600*1500 | Ф42*2.75*1636 | 5.44 | Q195 |

| A-XG-900*1500 | Ф42*2.75*1740 | 5.75 | Q195 | |

| A-XG-1200*1500 | Ф42*2.75*1889 | 6.12 | Q195 | |

| A-XG-1500*1500 | Ф42*2.75*2072 | 6.6 | Q195 | |

| A-XG-1800*1500 | Ф42*2.75*2281 | 7.16 | Q195 | |

| A-XG-2100*1500 | Ф42*2.75*2431 | 7.56 | Q195 | |

| 48 model Diagonal Brace | B-XG-600*1500 | Ф42*2.75*1637 | 5.44 | Q195 |

| B-XG-900*1500 | Ф42*2.75*1743 | 5.73 | Q195 | |

| B-XG-1200*1500 | Ф42*2.75*1892 | 6.12 | Q195 | |

| B-XG-1500*1500 | Ф42*2.75*2076 | 6.61 | Q195 | |

| B-XG-1800*1500 | Ф42*2.75*2285 | 7.17 | Q195 | |

| B-XG-2100*1500 | Ф42*2.75*2436 | 7.57 | Q195 | |

| Start collar (base collar) | ||||

| Name | Model | Size (mm) | Weight (kg) | Materials |

| 60 model Start collar | A-JZ-200 | Ф60*3.25*200 | 2.01 | Q355B |

| A-JZ-250 | Ф60*3.25*250 | 2.24 | Q355B | |

| 48 model Start collar | A-JZ-200 | Ф48*3.25*200 | 1.65 | Q355B |

| A-JZ-250 | Ф48*3.25*250 | 1.83 | Q355B | |

More parts and details if needed, please just feel free to contact with us, we will try our best to satisfy your requirement, for Steel Material Quick Use Ringlock Scaffolding Stage Scaffold

Components for High Quality of Steel Pedal for Steel Material Quick Use Ringlock Scaffolding Stage Scaffold

Customer feedback for ShanDong manufacturer High Quality of Steel Material Quick Use Ringlock Scaffolding Stage Scaffold

Shippment of Germany type Steel Construction Steel Pedal for Steel Material Quick Use Ringlock Scaffolding Stage Scaffold

Certificate Germany type High Quality of Steel Pedal for Steel Material Quick Use Ringlock Scaffolding Stage Scaffold

Best quality China ShanDong manufacturer Steel Pedal for Steel Material Quick Use Ringlock Scaffolding Stage Scaffold