- Overview

- Product Description

- Roof System Components (Light)

- Process

Basic Info.

Product Description

It is a complete system of weather protection, mainly made by bending, welding process, with high-altitude mesh structure, and cladding that protects construction sites and buildings and makes work both comfortable and safe in types of weather.

It is highly durable with long service life, easy to set up, can be pre-assembled at ground level and moved into place by crane.

Weather protection

Roof Systems are a robust temporary weather protection solution ideally suited to multiple applications in the residential, commercial, industrial, infrastructure and event sectors.

The roof system provides a quick, economical and easy to assemble solution to meet a diverse range of weather protection applications. The system is also modern and visually appealing, making it a great option for applications where site aesthetics are an important factor.

Easier and safer to assemble

Roof System's lightweight aluminium construction makes it easy to handle and significantly reduces assembly and disassembly times when compared to traditional protection methods. It also offers a safer means of installing roof sheets by removing the need to work on the top of the structure.

Cost effective

The flexibility of the system enables you to create protective roof structures, or combine it with sheet wall components to expand the system into a fully enclosed hall.

Roof System remains very cost effective, and the system's modular design, with just a small number of truss and bracing components, offers significant savings in build time and labour costs.

| Product Name | Aluminum Welding | |||

| Material | Alu1100/3003/5052/6063/6061, SUS304,SUS316 | |||

| Thickness | 0.5-20mm | |||

| Process Name | 1 | Incoming material inspection | 8 | MIG welding |

| 2 | Cutting | 9 | Painting | |

| 3 | Laser Cutting | 10 | Anodizing | |

| 4 | CNC machining | 11 | Installation | |

| 5 | Punching | 12 | Cleaning | |

| 6 | Bending | 13 | Inspection | |

| 7 | TIG welding | 14 | Delivery | |

| Drawing | Provide by customer, or design according to the sample | |||

| Drawing format | AutoCAD, SOLIDWORK, CAXA, UG, CAD, CAM, CAE, STP, IGES | |||

| Mould | Design and produce by ourself | |||

| Drawing time | 3 days | |||

| Sample time | 7-10 days | |||

| Lead time | 30 days | |||

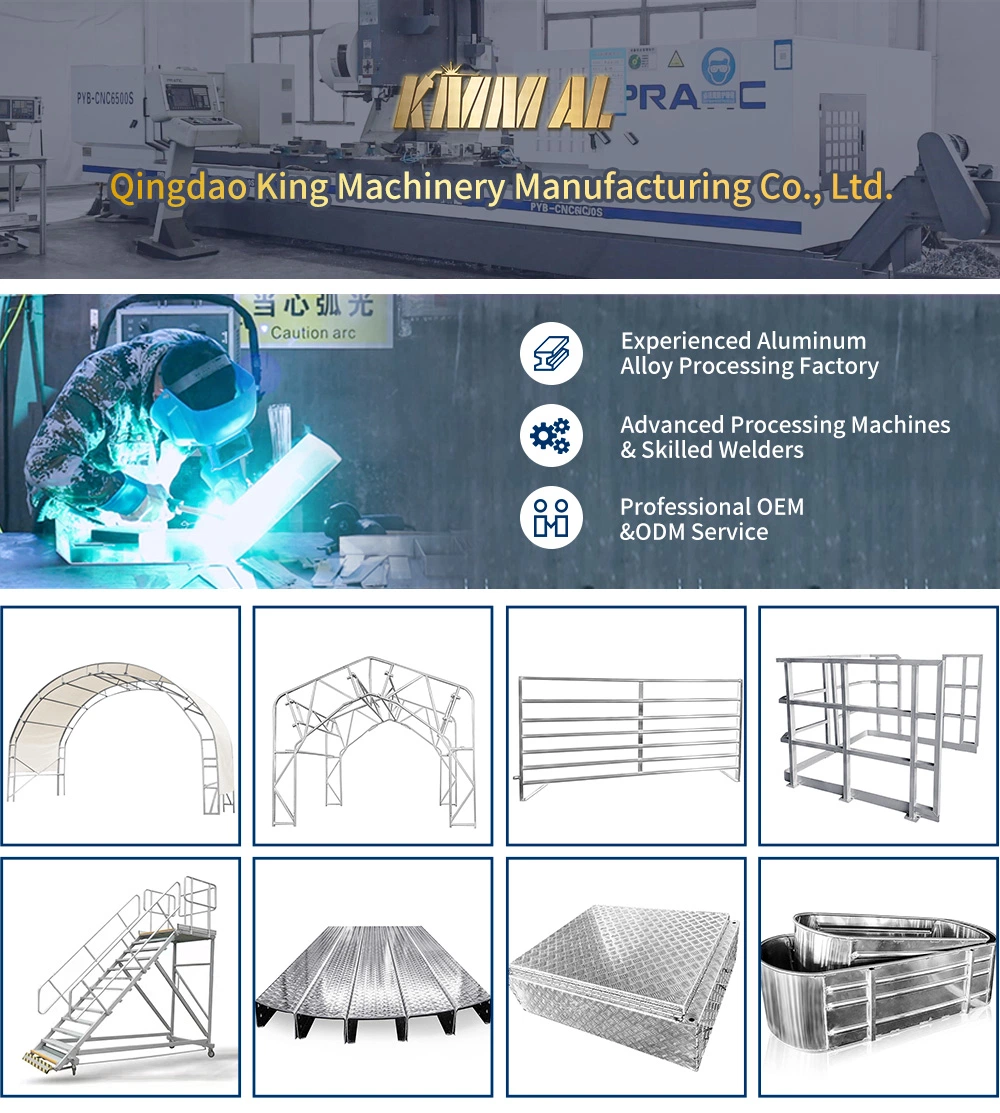

Qingdao King Machinery Manufacturing Co., Ltd. is a professional manufacturer integrating design, manufacturing, sales and service. It has stable supply chain, advanced aluminum alloy welding technology, and undertakes various types of aluminum alloy deep processing business. The team includes mechanical designers, quality management, welding engineers and other industry-related professionals.

The factory is located in Jiaoxi Town, Jiaozhou City, Qingdao, which is close to SCODA (China-SCO Local Economic and Trade Cooperation Demonstration Area) and provides supporting processing and other services to enterprises in the area.

Meanwhile, the factory has professional imported equipment,mainly equipped with 4 KW laser cutting machines, CNC shearing machines, plate bending machines, SY-VMC855 GNC, CNC lathes, ordinary lathes, 100T heavy-duty stamping equipment, welding robots, German LRCH welding machines, Finnish KEMPPI digital welding machines, etc.

The company's products involve construction, environmental protection equipment, new energy vehicles, aviation and other fields. The customized products are sold overseas, with its excellent product quality and service spirit, it has been widely recognized and praised by customers.