Basic Info.

Color

Blue,Red , Customized

Surface Treatment

Paint Spraying

Operation

Convernient to Operate

Certificate

ISO 9001

Transport Package

Standard Package

Specification

Customized

Trademark

Lianggong

Origin

Jiangsu, China

Production Capacity

5000 Tons /Month

Product Description

Product Description

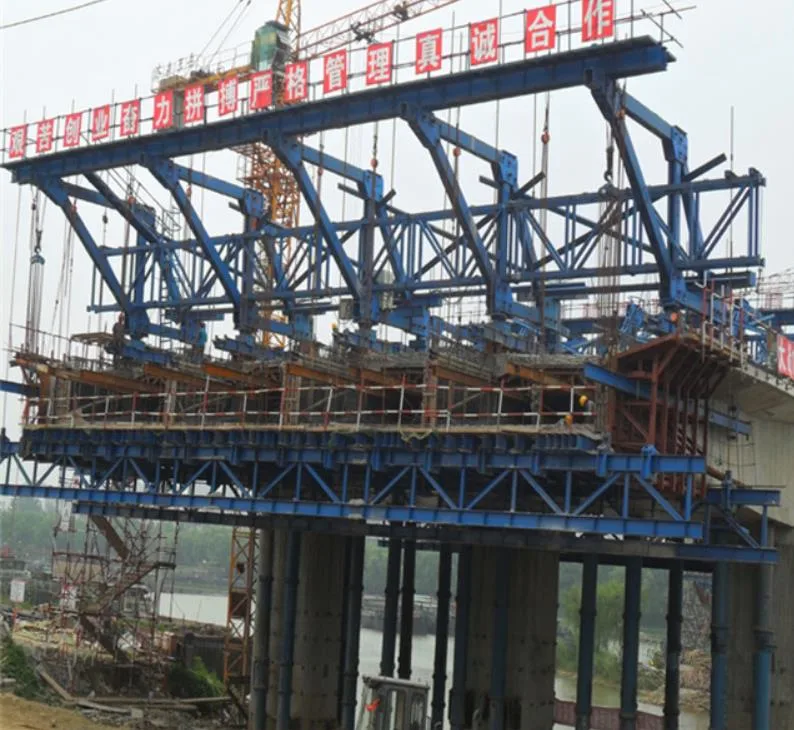

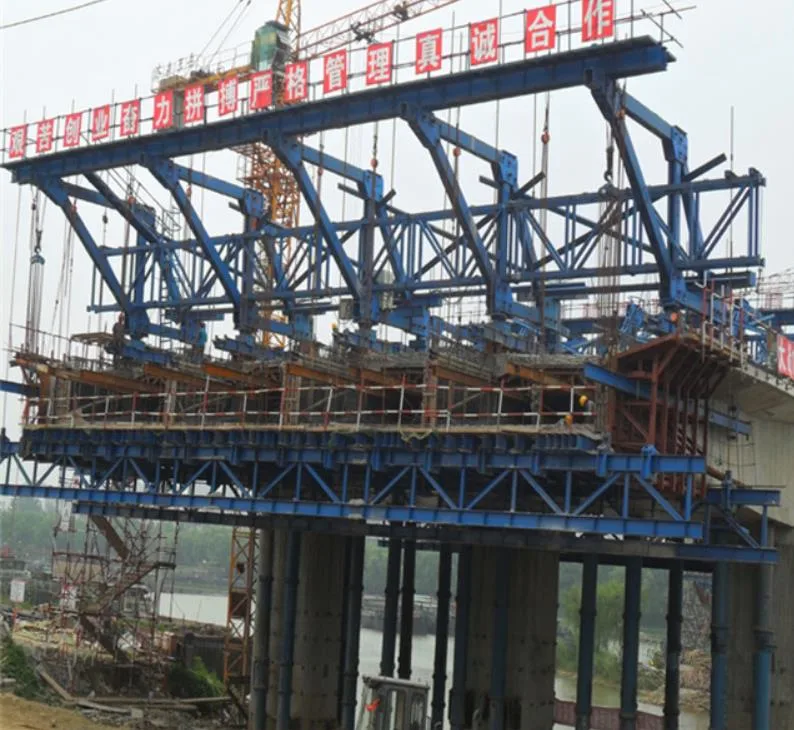

Cantilever Forming Traveller

Cantilever forming traveller is the main equipment in cantilever construction. According to the structure, they can be divided into four types: truss type, diagonal type, channel steel type and hybrid type. As per the requirements for cantilever construction and design drawings, comprehensive comparison of various cantilever forming travellers shall be done for their characteristics, weight, steel type, construction technology, etc. The principles of designing are to make them light-weighted with simple structure, firm and stable, easy to move forward, assemble and disassemble, with strong reusability, small deformation after loading, and sufficient space for operation under the traveller, and easy for rebar working.

Products Show

Characteristics

Cantilever forming traveler is widely used for the construction cast-in-site and balanced cantilever bridges.CFT can be customized to satisfy clients's requirement.According to the structure, they can be classified as truss traveler (including rhombic, triangular, bow-string etc.), cable stayed traveler (including triangular and pre-stressed), profile steel traveler and hybrid traveler.

1.Characteristics

(1)Reduced costs: because the equipment is rentable, it does not need to be pre-financed.

(2) Modular: Its modular components help it adapt flexibly to different geometries.

(3) Safety: the CFT's anchorages are hydraulically test-loaded before every pour.

2.Design Principles

(1)Light weight;

(2)Simple, strong and stable structure;

(3)Moved, mounted and stripped easily;

(4)Strong reusability;

(5) Small deformation under force;

(6)Adequate space under traveler and providing a big space for bars and formwork construction operation.

Packing & Delivery

Packaging:

1. Generally, the total net weight of loaded container is 22 tons to 25tons, which need be confirmed before loading.

2. Different packages are used for different products:

---Bundles: Timber beam, steel props, tie rod, etc.

---Pallet: Small parts will be put in bags and then on pallets.

---Wooden cases: It is available on customer's request.

---Bulk: Some irregular goods will be loaded in bulk in container.

Delivery:

1. Production: For full container, normally we need 20-30 days after receive customer's down payment.

2. Transportation: It depends on the destination charge port.

3. Negotiation is needed for special requirements.

Packaging:

1. Generally, the total net weight of loaded container is 22 tons to 25tons, which need be confirmed before loading.

2. Different packages are used for different products:

---Bundles: Timber beam, steel props, tie rod, etc.

---Pallet: Small parts will be put in bags and then on pallets.

---Wooden cases: It is available on customer's request.

---Bulk: Some irregular goods will be loaded in bulk in container.

Delivery:

1. Production: For full container, normally we need 20-30 days after receive customer's down payment.

2. Transportation: It depends on the destination charge port.

3. Negotiation is needed for special requirements.

Our Service

1.Consulting,Design,and Quotation

Offer you a general idea of formwork & scaffold among LiangGong various systems, to fit your project demand.Design and Customized forming & shoring proposal according to your structural drawing by Auto-CAD.

2.Manufacture and Quality Inspection

Large-scale production workshop and First-class production line, as well as a professional quality inspection team, which will provide you with high quality standard products.

Test report will be available according to different norms from different regions in order to offer no worries to clients or meet destination authority requirements.

3.Packing and Shipment

From fabrication to loading, use standard export packages to get to your site quickly.

4.Remote or On-site instruction

If you have any questions, we can provide remote or on-site guidance. Our aim is to make customers feel at ease and satisfied throughout the process.

1.Consulting,Design,and Quotation

Offer you a general idea of formwork & scaffold among LiangGong various systems, to fit your project demand.Design and Customized forming & shoring proposal according to your structural drawing by Auto-CAD.

2.Manufacture and Quality Inspection

Large-scale production workshop and First-class production line, as well as a professional quality inspection team, which will provide you with high quality standard products.

Test report will be available according to different norms from different regions in order to offer no worries to clients or meet destination authority requirements.

3.Packing and Shipment

From fabrication to loading, use standard export packages to get to your site quickly.

4.Remote or On-site instruction

If you have any questions, we can provide remote or on-site guidance. Our aim is to make customers feel at ease and satisfied throughout the process.

Our Company

Customer Photos

FAQ