Basic Info.

Model NO.

BS205

Supporting Mode

Scaffolding

Lapping Form

Installation Scaffold

Erection Position

Internal Scaffolding

Move Method

Horizontal mobile Scaffolding

Scaffolding Part Type

Scaffolding Props

Construction Properties

Building Scaffold

Transport Package

Container

Trademark

bythai

Origin

China

Product Description

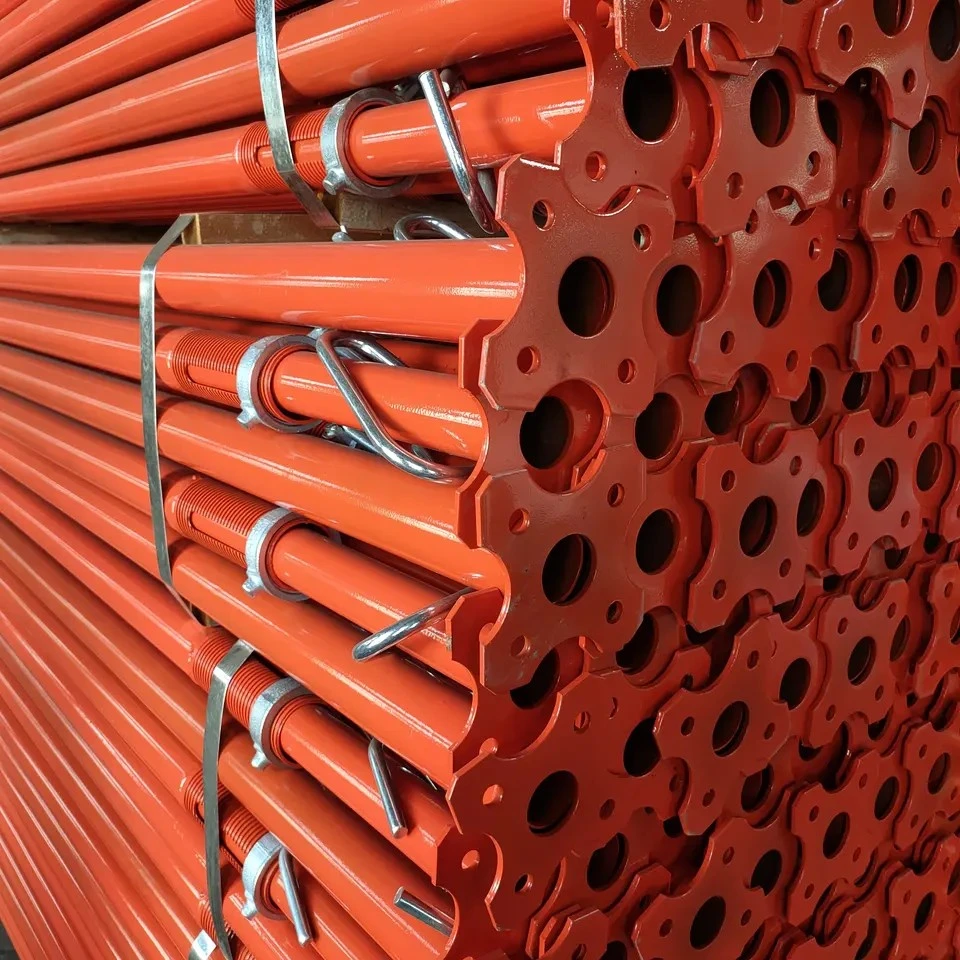

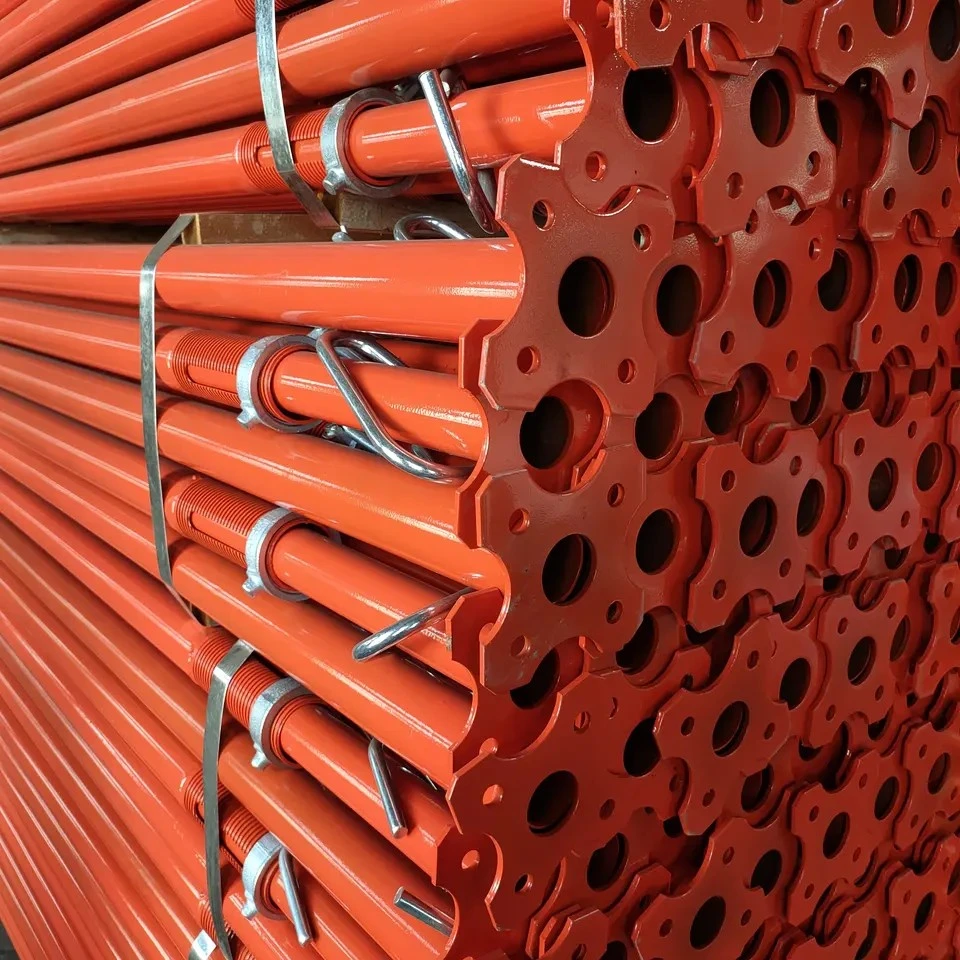

Scaffolding Steel props

product description:

Scaffolding steel supports are an essential construction tool used to provide support and stability to temporary work platforms and structures. Our range of scaffolding steel supports is renowned for its superior quality, diverse specifications and wide range of applications.

Specifications and dimensions:

Materials: We offer two main steel options including durable Q235 and strong Q355B.

Lengths: Our products are available in a variety of length options including 40mm, 48mm, 56mm, 60mm, 70mm, 76mm and 89mm to meet a variety of support needs.

Surface treatment: Customers can choose surface treatment of spraying process, galvanizing, pre-galvanizing or hot-dip galvanizing to adapt to different environments.

Performance features:

Our scaffolding steel supports offer outstanding performance features including:

- High load-bearing capacity to ensure the stability of the working platform.

- Corrosion resistance, suitable for different climate and environmental conditions.

-A variety of specifications to choose from to meet various engineering needs.

- Durability ensures long-term use and excellent performance.

Materials and Manufacturing Process:

We use high-quality Q235 and Q355B steel and undergo exquisite manufacturing processes to ensure the consistency and reliability of product quality. Our product manufacturing process follows the highest quality standards to meet the requirements of our customers.

Usage and installation instructions:

We provide detailed usage and installation instructions to ensure customers can install and use the product correctly, including safe operating recommendations and schematics.

Maintenance and Care: Check for Corrosion and Damage: Regularly inspect support rods, threads, nuts and other components to ensure there is no corrosion, rust or obvious damage. If any problems are found, damaged parts should be repaired or replaced promptly.

Lubrication: Regularly lubricate threads and other moving parts of supports to ensure they operate smoothly. Use appropriate lubricants or greases to prevent wear and corrosion.

Avoid overuse: Scaffolding supports have a limited maximum load and range of use, and overuse should be avoided to reduce the risk of damage and accidents.

Storage and transportation: When not using supports, store in a dry, ventilated place protected from sunlight and rain. During transportation, be careful to avoid collision and damage.

Regular Inspections: Conduct comprehensive inspections on a regular basis to ensure the safety and availability of supports. If there are any problems, prompt measures should be taken to repair or replace damaged parts.

AFQ

AFQ

1. : What types of scaffolding services does your company provide?

We provide many types of scaffolding services, including cantilever scaffolding, portal scaffolding, cantilever scaffolding, etc., as well as disc systems, steel treads, fasteners, steel supports and other products.

2. :What safety standards does your company's scaffolding comply with?

We strictly follow international, national and local safety standards to ensure that all scaffolding operations comply with relevant regulations and safety requirements.

3.: How to get a quotation from your company?

You can submit project details through the online quotation form on our official website, or contact our sales team directly for detailed quotation information.

4. :What successful scaffolding project experience does your company have?

We have been involved in many successful projects over the past three years including multi-storey buildings, bridge projects and more. Please refer to our project case page for specific cases.

5: Does your company provide services for customized scaffolding products?

Yes, we can provide customized scaffolding products according to customers' specific needs, including customization of size, shape and load capacity.

product description:

Scaffolding steel supports are an essential construction tool used to provide support and stability to temporary work platforms and structures. Our range of scaffolding steel supports is renowned for its superior quality, diverse specifications and wide range of applications.

Specifications and dimensions:

Materials: We offer two main steel options including durable Q235 and strong Q355B.

Lengths: Our products are available in a variety of length options including 40mm, 48mm, 56mm, 60mm, 70mm, 76mm and 89mm to meet a variety of support needs.

Surface treatment: Customers can choose surface treatment of spraying process, galvanizing, pre-galvanizing or hot-dip galvanizing to adapt to different environments.

Performance features:

Our scaffolding steel supports offer outstanding performance features including:

- High load-bearing capacity to ensure the stability of the working platform.

- Corrosion resistance, suitable for different climate and environmental conditions.

-A variety of specifications to choose from to meet various engineering needs.

- Durability ensures long-term use and excellent performance.

Materials and Manufacturing Process:

We use high-quality Q235 and Q355B steel and undergo exquisite manufacturing processes to ensure the consistency and reliability of product quality. Our product manufacturing process follows the highest quality standards to meet the requirements of our customers.

Usage and installation instructions:

We provide detailed usage and installation instructions to ensure customers can install and use the product correctly, including safe operating recommendations and schematics.

Maintenance and Care: Check for Corrosion and Damage: Regularly inspect support rods, threads, nuts and other components to ensure there is no corrosion, rust or obvious damage. If any problems are found, damaged parts should be repaired or replaced promptly.

Lubrication: Regularly lubricate threads and other moving parts of supports to ensure they operate smoothly. Use appropriate lubricants or greases to prevent wear and corrosion.

Avoid overuse: Scaffolding supports have a limited maximum load and range of use, and overuse should be avoided to reduce the risk of damage and accidents.

Storage and transportation: When not using supports, store in a dry, ventilated place protected from sunlight and rain. During transportation, be careful to avoid collision and damage.

Regular Inspections: Conduct comprehensive inspections on a regular basis to ensure the safety and availability of supports. If there are any problems, prompt measures should be taken to repair or replace damaged parts.

AFQ

AFQ 1. : What types of scaffolding services does your company provide?

We provide many types of scaffolding services, including cantilever scaffolding, portal scaffolding, cantilever scaffolding, etc., as well as disc systems, steel treads, fasteners, steel supports and other products.

2. :What safety standards does your company's scaffolding comply with?

We strictly follow international, national and local safety standards to ensure that all scaffolding operations comply with relevant regulations and safety requirements.

3.: How to get a quotation from your company?

You can submit project details through the online quotation form on our official website, or contact our sales team directly for detailed quotation information.

4. :What successful scaffolding project experience does your company have?

We have been involved in many successful projects over the past three years including multi-storey buildings, bridge projects and more. Please refer to our project case page for specific cases.

5: Does your company provide services for customized scaffolding products?

Yes, we can provide customized scaffolding products according to customers' specific needs, including customization of size, shape and load capacity.