Basic Info.

Supporting Mode

Floor Type Scaffolding

Lapping Form

Full Scaffolding

Erection Position

External Scaffolding

Move Method

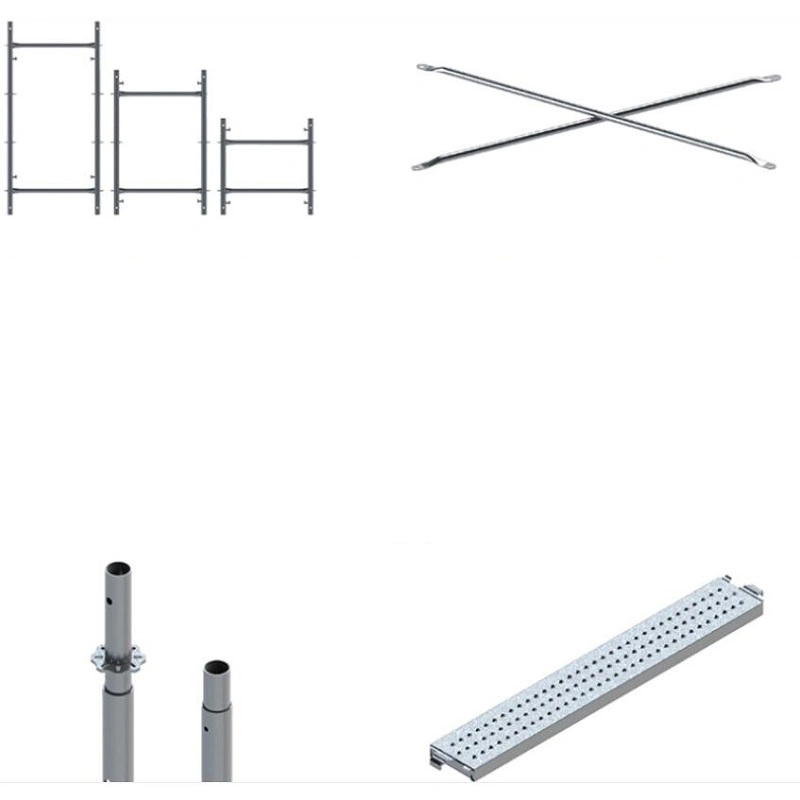

Scaffolding Frame

Scaffolding Part Type

Scaffolding Frames

Construction Properties

Building Scaffold

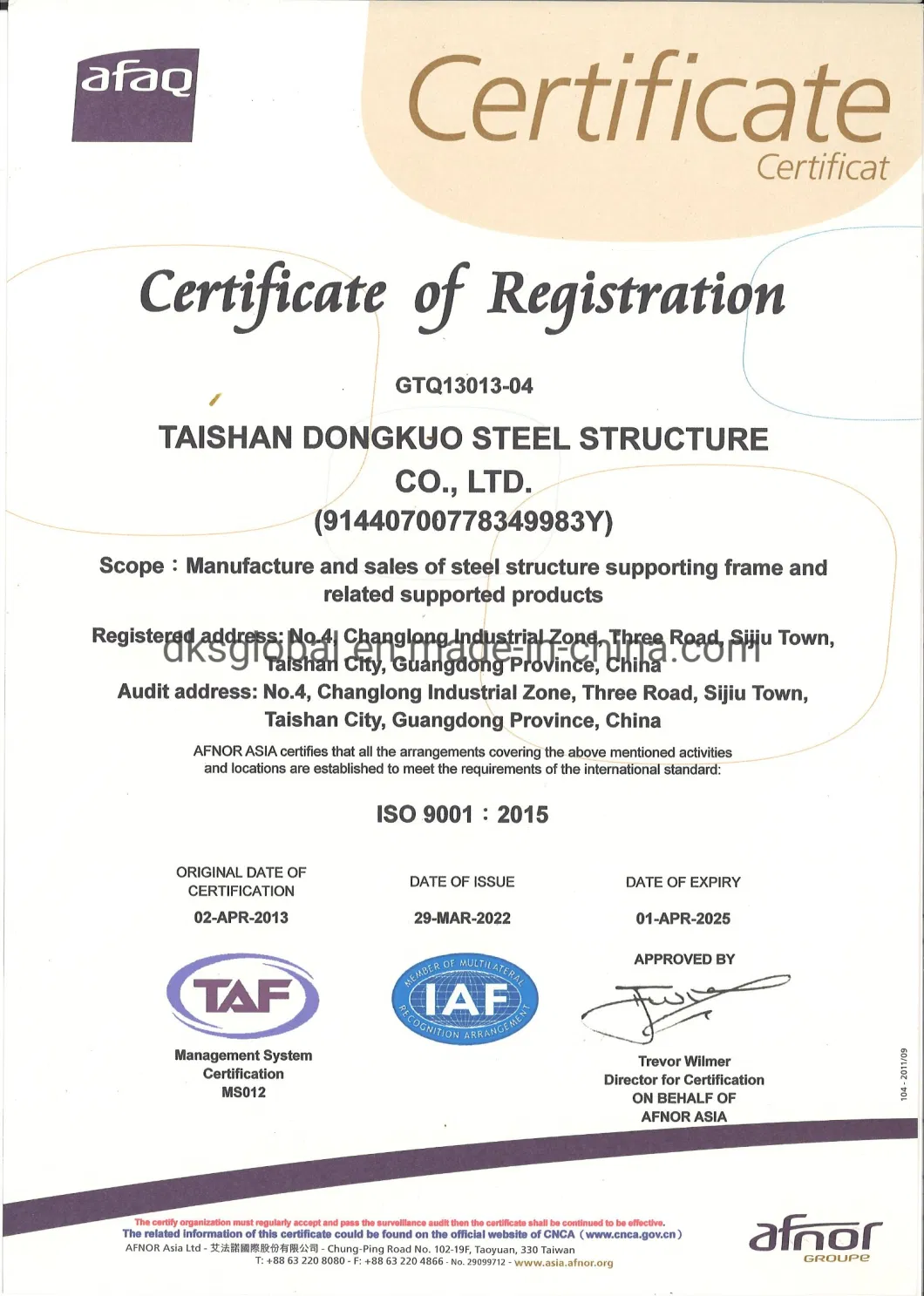

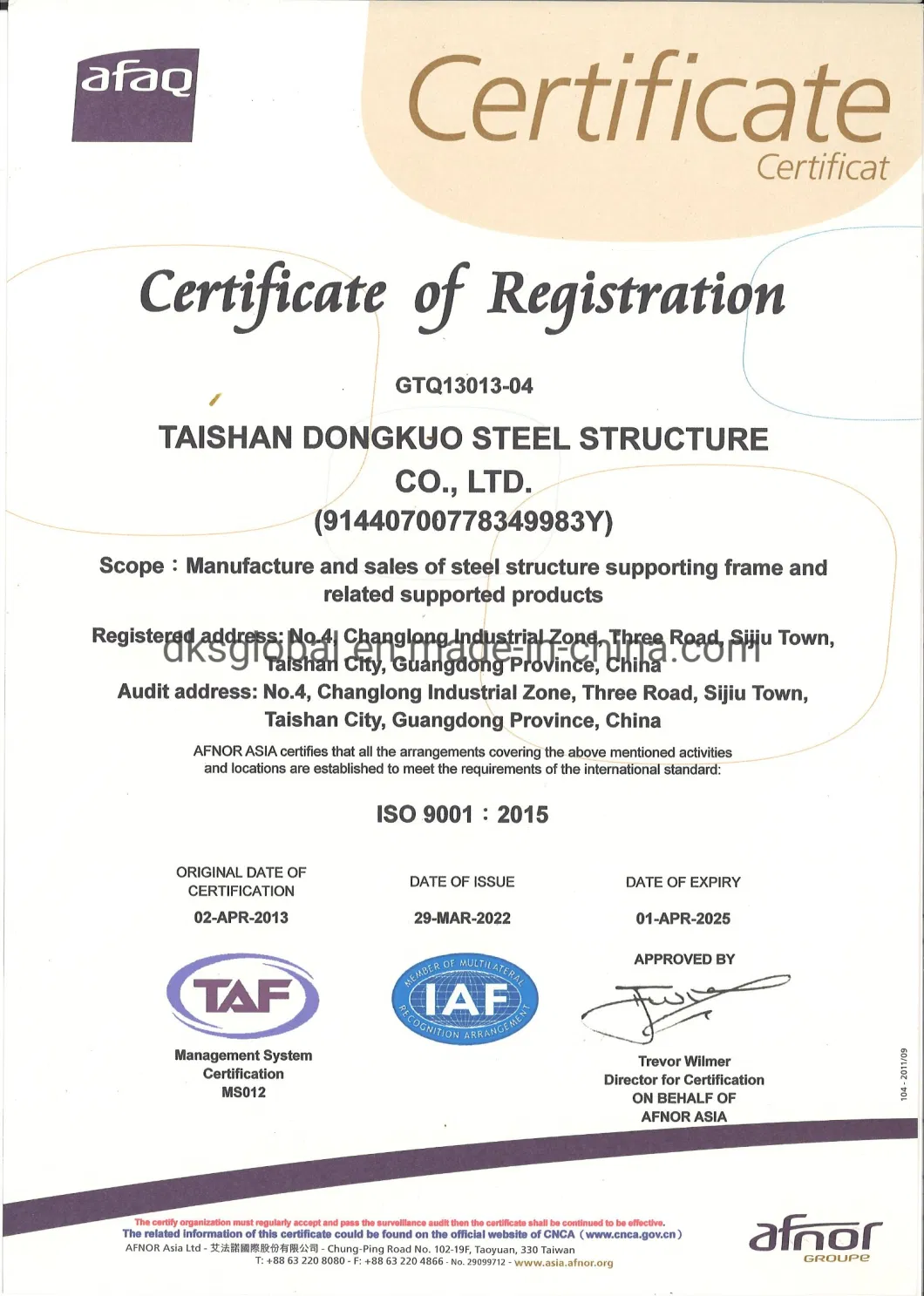

Certified

ISO9001

Usage

Loading Platforms

Scaffold

Building Material/ Construction

Concrete

Bridge Decks

Transport Package

Normal Package

Specification

19.2kg

Trademark

OEM/ODM

Origin

China

HS Code

76169990

Production Capacity

50 Ton / Month

Product Description

Building material H frame scaffold components aluminum concrete scaffolding system working platforms

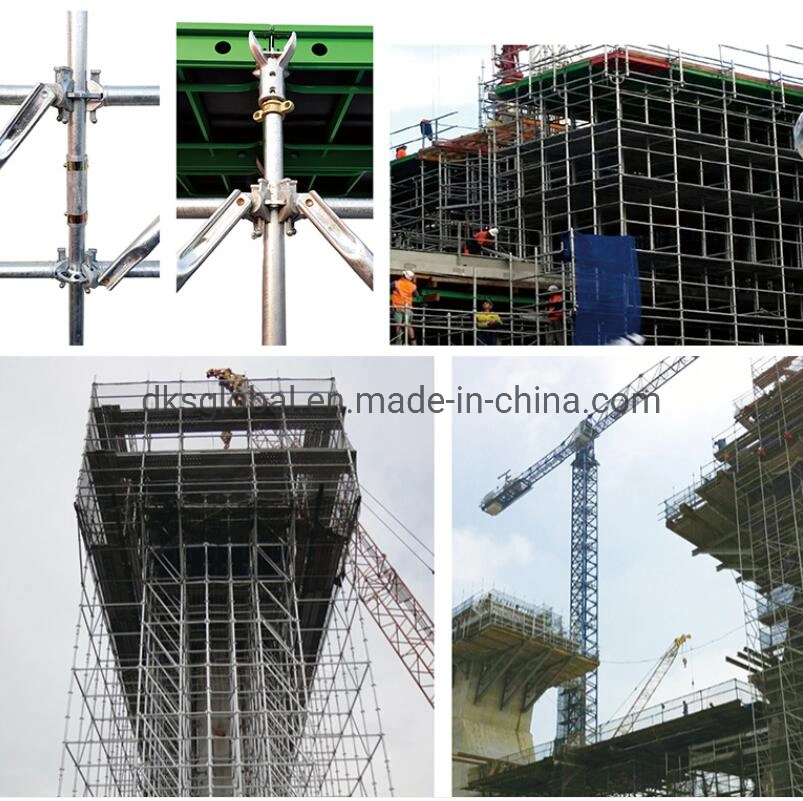

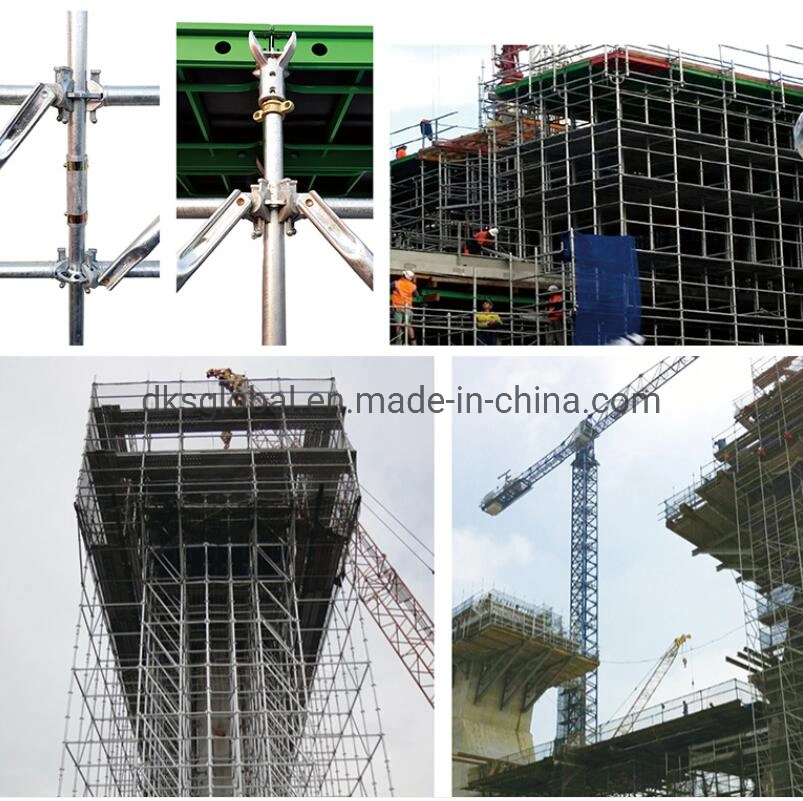

Engineered for versatility and durability, the Ring Frame is ideal for structures with complex shapes, plans and heights. Whether as a scaffold or a shoring system, it is the perfect choice when angular flexibility is essential.

Unlimited possibilities

At the core of the Ring Frame System is the rosette design. This unique plate has eight apertures that can link up to eight horizontal and diagonal to each rosette. In other words, the Ring Frame System offers virtually unlimited angular fitting and design, making it the perfect scaffold for triangular, polygonal and curved structures.

Manufactured to last

All Ring Frame System components are galvanized and therefore offer excellent anti-corrosion resistance. This protection reduces maintenance costs, extends lifespan and therefore enables longer utilization.

A strong and safe connection system

The Ring Frame system uses a wedge shaped system to ensure a safe and reliable connection(e.g. cannot be accidentally dislodged) between standards, ledgers and diagonal braces.

A comprehensive range

As a versatile manufacturer and inventor of modular scaffolding systems, DKS also provides a complete range of components such as e.g. panels, crowns and supports.

Dimensions

13.Base-Jacks

ISO Certificate

ISO Certificate

Factory

https://dksglobal.en.made-in-china.com/company-Taishan-Dongkuo-Steel-Structure-Co-Ltd-.html

DKS was established in 2005, located in Taishan, Guangdong Province, with convenient transportation and only two hours from Guangzhou.

DKS is committed to the production and marketing of scaffolding system, shoring system and formwork system including steel ringlock system, Mega beam, waler beam, shoring jack and others, Also other aluminum scaffolding products.

The factory is also equiped with modern and high-performance production tools and is ISO 9001 certified.

With ISO9001 and other qualifications, professional R&D and QC team can guanantee the quantity of products.

With ISO9001 and other qualifications, professional R&D and QC team can guanantee the quantity of products.

With 15 years of export experience in scaffolding production, DKS products are exported to the United States,USA, Australia, Germany, Japan, Spain and many other countries.

https://dksglobal.en.made-in-china.com/product-list-1.html

DKS aims to ensure safety in every work site alsong with its mission to bring happiness to its employees and contribute to society.

DKS adhere to the management principles of "quality first, ccustomer first and credit based" since the establishment of the company and always do our best to satisfy potential needs of our customers. DKS is sincerely willing to cooperate with enterprises from all over the world in order to realize a win-win situation since the trend of economic globalization has developed with anirresistible force.

FAQ

1. What's your MOQ?

MOQ is required for customized products(30 ton)

2. What's your payment terms?

30% deposit, balance before delivery.

3. What's your delivery time?

It depends on products, 45days to 70days after confirmed the order

4. Where is your factory?

Our company is located in Taishan,Guangdong. Two hours to Guangzhou, shenzhen, four hours to Hongkong.

5. Can we visit your factory?

Of course! Also we can help you to arrange airport pick up and hotel booking.

6. Can you accept OEM/ODM?

Yes, of course!

https://dksglobal.en.made-in-china.com/company-Taishan-Dongkuo-Steel-Structure-Co-Ltd-.html

Engineered for versatility and durability, the Ring Frame is ideal for structures with complex shapes, plans and heights. Whether as a scaffold or a shoring system, it is the perfect choice when angular flexibility is essential.

Unlimited possibilities

At the core of the Ring Frame System is the rosette design. This unique plate has eight apertures that can link up to eight horizontal and diagonal to each rosette. In other words, the Ring Frame System offers virtually unlimited angular fitting and design, making it the perfect scaffold for triangular, polygonal and curved structures.

Manufactured to last

All Ring Frame System components are galvanized and therefore offer excellent anti-corrosion resistance. This protection reduces maintenance costs, extends lifespan and therefore enables longer utilization.

A strong and safe connection system

The Ring Frame system uses a wedge shaped system to ensure a safe and reliable connection(e.g. cannot be accidentally dislodged) between standards, ledgers and diagonal braces.

A comprehensive range

As a versatile manufacturer and inventor of modular scaffolding systems, DKS also provides a complete range of components such as e.g. panels, crowns and supports.

Dimensions

- Standards

| Code | Description | Tube size & Weight | Tube size & Weight | |

| DRF-S-3000 | 118.1 in | RF Standard 3000mm | 1.9(in)x3.2t & 29.5lb 13.37kg | 2.4(in)x3.2t & 35.7lb 16.2kg |

| DRF-S-2500 | 98.4 in | RF Standard 2500mm | 1.9(in)x3.2t & 24.6lb 11.14kg | 2.4(in)x3.2t & 29.8lb 13.5kg |

| DRF-S-2000 | 78.7 in | RF Standard 2000mm | 1.9(in)x3.2t & 19.7lb 8.92kg | 2.4(in)x3.2t & 23.8lb 10.8kg |

| DRF-S-1500 | 59.1 in | RF Standard 1500mm | 1.9(in)x3.2t & 14.7lb 6.69kg | 2.4(in)x3.2t & 17.9lb 8.1kg |

| DRF-S-1000 | 39.4 in | RF Standard 1000mm | 1.9(in)x3.2t & 9.8lb 4.46kg | 2.4(in)x3.2t & 11.9lb 5.4kg |

| DRF-S-500 | 19.7 in | RF Standard 500mm | 1.9(in)x3.2t & 4.9lb 2.23kg | 2.4(in)x3.2t & 1.0lb 2.7kg |

- Ledgers

| Code | Description | Weight | ||

| DRF-L-2440 | 96.1 in | RF Ledgers 2440mm | 20.9 lb | 9.50 kg |

| DRF-L-1830 | 72.0 in | RF Ledgers 1830mm | 15.4 lb | 7.00 kg |

| DRF-L-1220 | 48.0 in | RF Ledgers 1220mm | 11.01 lb | 5.00 kg |

| DRF-L-900 | 35.4 in | RF Ledgers 900mm | 8.8 lb | 4.00 kg |

| DRF-L-600 | 23.6 in | RF Ledgers 600mm | 7.0 lb | 3.20 kg |

| DRF-L-300 | 11.8 in | RF Ledgers 300mm | 4.4 lb | 2.00 kg |

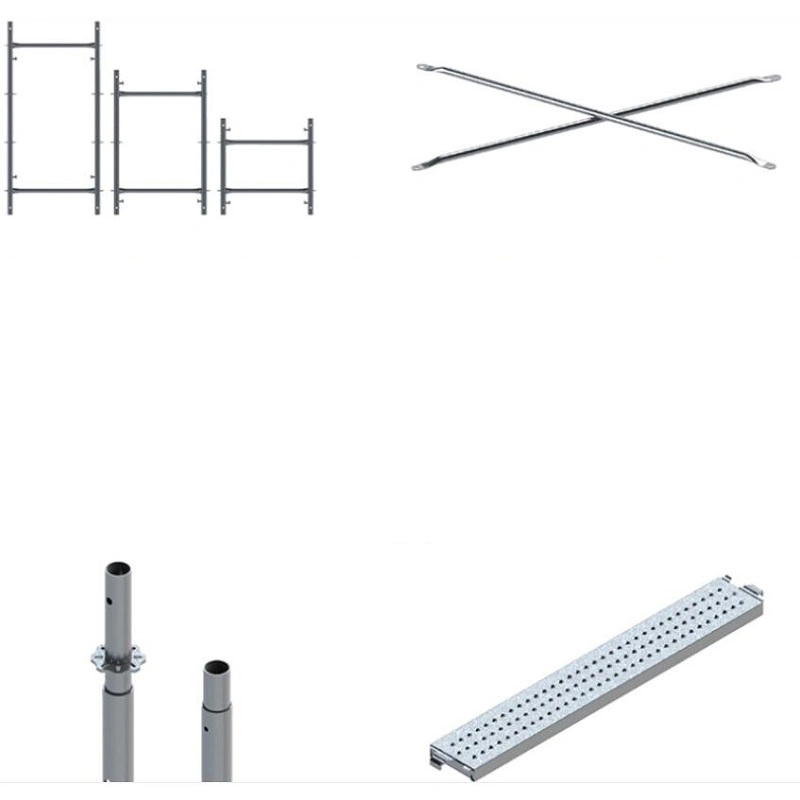

- Frames

| Code | Description | Tube size & Weight | Tube size & Weight | |

| DRF-F-2000 | 78.7 in | RF Frames 3000m | 1.9(in)x3.2t 52.6lb 23.88kg | 2.4(in)x3.2t 60.9lb 27.64kg |

| DRF-F-1500 | 59.1 in | RF Frames 1500m | 1.9(in)x3.2t 42.8lb 19.42kg | 2.4(in)x3.2t 49.0lb 22.24kg |

| DRF-F-1000 | 39.4 in | RF Frames 1000m | 1.9(in)x3.2t 33.0lb 14.96kg | 2.4(in)x3.2t 37.0lb 16.78kg |

- Braces

| Code | Description | Weight | |

| DRF-XB-1679 | RF Braces 1679mm | 9.2 lb | 4.20 kg |

| DRF-XB-1952 | RF Braces 1952mm | 10.5 lb | 4.80 kg |

| DRF-XB-2554 | RF Braces 2554mm | 14.1 lb | 6.40 kg |

- Spigot

| Code | Description | Weight | |

| DRF-KSET | Brace Collar | 11.4 lb | 5.20 kg |

| DRF-KSET500 | RF Spigot 500mm | 20.9 lb | 9.50 kg |

- Boards

| Code | Description | Weight | ||

| DRF-B-2440 | 96.1 in | RF Boards 2440mm | 36.4 lb | 16.50kg |

| DRF-B-1830 | 72.0 in | RF Boards 1830mm | 27.6 lb | 12.50kg |

- Hop Up Brackets

| Code | Description | Weight | ||

| DRF-HU-600 | 23.6 in | RF Hop Up Brackets 600mm | 36.4 lb | 16.50 kg |

| DRF-HU-300 | 11.8 in | RF Hop Up Brackets 300mm | 27.6 lb | 12.50 kg |

- Braces

| Code | Description | Weight | ||

| DRF-B-2000 | 78.7in x 34.5in | RF Braces 2000mm x 900mm | 21.0 lb | 9.50 kg |

| DRF-B-2000 | 78.7in x 72.05in | RF Braces 2000mm x 1830mm | 25.0lb | 11.34 kg |

| DRF-B-2000 | 59.1in x35.4in | RF Braces 1500mm x 900mm | 18.5 lb | 8.40 kg |

- Crown

| Code | Description | Weight | |

| DRF-KSFC | RF Crown | 2.4 lb | 1.10kg |

- Mega Panel (material: AL6082-T6)

| Code | Description | Weight | ||

| DRF-MP-1809 | 70.9 X 35.4in | 1800 x 900mm | 87.5 lb | 39.7kg |

| DRF-MP-1806 | 70.9 X 23.6in | 1800 x 600mm | 57.3 lb | 36.0kg |

| DRF-MP-1803 | 70.9 X 11.8in | 1800 x 300mm | 38.4 lb | 17.4kg |

| DRF-MP-1209 | 70.9 X 35.4in | 1800 x 900mm | 56.7 lb | 25.7kg |

| DRF-MP-1806 | 70.9 X 23.6in | 1800 x 600mm | 42.3 lb | 19.2kg |

- Light Panel (material: AL6061-T6)

| Code | Description | Weight | ||

| DRF-LP-1809 | 70.9 X 35.4in | 1800 x 900mm | 55.6 lb | 25.2kg |

| DRF-LP-1806 | 70.9 X 23.6in | 1800 x 600mm | 41.1 lb | 18.64kg |

| DRF-LP-1803 | 70.9 X 11.8in | 1800 x 300mm | 28.1 lb | 12.76kg |

| DRF-LP-1809 | 70.9 X 35.4in | 1800 x 900mm | 30.9 lb | 14.0kg |

| DRF-LP-1806 | 70.9 X 23.6in | 1800 x 600mm | 23.1 lb | 10.48kg |

| DRF-LP-1803 | 70.9 X 11.8in | 1800 x 300mm | 15.2 lb | 6.91kg |

- U - Jacks

| Code | Description | Weight | |

| DRF-KSUJ | RF-U -JACKS | 11.8 lb | 5.35kg |

13.Base-Jacks

| Code | Description | Weight | |

| DRF-KSBJ | RF-BASE-JACK | 9.37lb | 4.25kg |

ISO Certificate

ISO Certificate

Factory

https://dksglobal.en.made-in-china.com/company-Taishan-Dongkuo-Steel-Structure-Co-Ltd-.html

DKS was established in 2005, located in Taishan, Guangdong Province, with convenient transportation and only two hours from Guangzhou.

DKS is committed to the production and marketing of scaffolding system, shoring system and formwork system including steel ringlock system, Mega beam, waler beam, shoring jack and others, Also other aluminum scaffolding products.

The factory is also equiped with modern and high-performance production tools and is ISO 9001 certified.

With ISO9001 and other qualifications, professional R&D and QC team can guanantee the quantity of products.

With ISO9001 and other qualifications, professional R&D and QC team can guanantee the quantity of products. With 15 years of export experience in scaffolding production, DKS products are exported to the United States,USA, Australia, Germany, Japan, Spain and many other countries.

https://dksglobal.en.made-in-china.com/product-list-1.html

DKS aims to ensure safety in every work site alsong with its mission to bring happiness to its employees and contribute to society.

DKS adhere to the management principles of "quality first, ccustomer first and credit based" since the establishment of the company and always do our best to satisfy potential needs of our customers. DKS is sincerely willing to cooperate with enterprises from all over the world in order to realize a win-win situation since the trend of economic globalization has developed with anirresistible force.

FAQ

1. What's your MOQ?

MOQ is required for customized products(30 ton)

2. What's your payment terms?

30% deposit, balance before delivery.

3. What's your delivery time?

It depends on products, 45days to 70days after confirmed the order

4. Where is your factory?

Our company is located in Taishan,Guangdong. Two hours to Guangzhou, shenzhen, four hours to Hongkong.

5. Can we visit your factory?

Of course! Also we can help you to arrange airport pick up and hotel booking.

6. Can you accept OEM/ODM?

Yes, of course!

https://dksglobal.en.made-in-china.com/company-Taishan-Dongkuo-Steel-Structure-Co-Ltd-.html